Thinking of launching your own DIY lash brand but overwhelmed by finding reliable wholesale suppliers? It’s a common hurdle, and the wrong choice can stall your business before it even starts.

Sourcing wholesale DIY lash clusters effectively means partnering directly with reputable factories or specialized suppliers, primarily in China, who can offer customization, quality control, and competitive pricing for your brand. This guide will walk you through the essentials.

Navigating the world of wholesale can be tricky, but it’s the key to building a profitable DIY lash business. As someone who works with UBLash, a company specializing in private label lash products, I’ve learned a lot about this process. Let’s break down what you need to know to find the best partners and products.

What Are the Minimum Order Quantities (MOQs) for Wholesale DIY Lash Manufacturers?

Worried about committing to huge orders when you’re just starting your DIY lash line? Understanding MOQs is crucial for managing your budget and inventory effectively.

Minimum Order Quantities (MOQs) for wholesale DIY lash manufacturers vary significantly based on the factory, product complexity, and customization level. For basic DIY lash clusters, MOQs might start from 50-100 units per style, while highly customized or private label orders could be higher. [3]

When I first explored sourcing for UBLash, MOQs were a big factor. It’s a balancing act. You want enough stock, but you don’t want to overextend your finances. It’s always best to discuss directly with potential suppliers.

Understanding MOQ Variations:

MOQs aren’t arbitrary; they reflect the manufacturer’s costs and production efficiencies. Several factors influence them:

- Product Type1: Standard, in-stock DIY lash styles will typically have lower MOQs than brand-new, custom-designed clusters.

- Customization2: The more bespoke your requirements (e.g., unique lash mapping, special fibers, intricate packaging), the higher the MOQ is likely to be. This is because custom molds, materials, or printing setups have initial costs for the factory. [3]

- Packaging3: Simple, generic packaging might allow for lower MOQs. Custom-printed boxes or unique container shapes will almost certainly require a larger order to be cost-effective for the manufacturer. [5]

- Manufacturer Scale: Larger, more established factories might have higher MOQs due to their production line setups, while smaller or more flexible workshops might offer lower MOQs to attract new businesses.

| Factor Affecting MOQ | Typical Impact on MOQ | Why? |

|---|---|---|

| Standard DIY Styles | Lower | Existing production lines, readily available materials. |

| Custom DIY Styles | Higher | New designs may require tooling, specific fiber sourcing. |

| Basic Packaging | Lower | Generic options are often stocked. |

| Custom Packaging | Higher | Costs of custom printing plates, dies, unique materials. [5] |

| Raw Material Costs | Can influence (specialty fibers higher) | Unique or premium materials might need to be bought in bulk by factory. |

My advice, especially for someone like Sophie starting her brand, is to be upfront about your expected volume and growth. Many manufacturers, including us at UBLash for our B2B clients, are willing to negotiate or offer starter packages, particularly if they see long-term potential. Always ask!

What Types of Lash Materials Do Wholesale DIY Lash Manufacturers Commonly Offer?

Concerned about the quality and feel of the DIY lashes you’ll be selling? The material is everything, and knowing your options is key to meeting your customers’ expectations.

Wholesale DIY lash manufacturers commonly offer materials like high-quality PBT (Polybutylene Terephthalate), often marketed as "faux mink" or "silk" lashes. Some may also offer real mink (though less common for DIY due to cost/ethics) or other synthetic fibers.

%[alt text with descriptive keywords: Close-up shots of different lash materials like PBT, faux mink, and silk fibers]](http://ublash.com/wp-content/uploads/2024/05/starseed-eyelashes-materials-1024×683.jpeg)

At UBLash, we primarily focus on premium PBT for its softness, durability, and ability to hold a curl – all crucial for DIY lash clusters that need to look good and last. The "best" material often depends on the desired look, feel, and price point of your DIY lash kits.

Popular DIY Lash Materials:

The DIY lash market values ease of application, comfort, and a natural yet enhanced look. Here’s a breakdown of common materials:

- PBT (Polybutylene Terephthalate)1: This is the workhorse of the lash industry.

- Qualities: Soft, lightweight, excellent curl retention, consistent quality, can be made very fine for a natural look. Often used to create "faux mink" or "silk" finishes. It’s durable and hypoallergenic.

- Why for DIY? Perfect for segments that need to be picked up and placed easily, hold their shape, and feel comfortable for extended wear (several days for some DIY systems).

- "Faux Mink2" (usually PBT): These are PBT lashes specifically processed to mimic the softness, matte finish, and tapered tips of real mink fur.

- Qualities: Very soft, luxurious feel, natural appearance.

- Why for DIY? Offers a premium experience, ideal for users wanting a fluffy, high-end look without the ethical or consistency issues of real mink.

- "Silk" Lashes (usually PBT): Typically PBT lashes with a slightly more lustrous or glossier finish compared to faux mink. They can also be very lightweight and flexible.

- Qualities: Lightweight, flexible, often a bit more sheen.

- Why for DIY? Good for achieving a more defined or subtly glamorous look. The term is more about the finish than a distinct base material from PBT.

- Other Synthetics: Occasionally, very low-cost DIY kits might use other basic synthetic fibers, but these generally don’t offer the same quality, softness, or curl retention as PBT.

| Material | Common Market Name(s) | Key Characteristics for DIY Lashes | UBLash Focus |

|---|---|---|---|

| PBT | Synthetic, Korean PBT | Soft, durable, great curl retention, consistent, hypoallergenic | Yes (Primary) |

| PBT (Faux Mink) | Faux Mink | Ultra-soft, matte, tapered, luxurious feel, natural look | Yes (Specialty) |

| PBT (Silk) | Silk Lashes | Lightweight, flexible, slight sheen, defined look | Yes (As a finish) |

Given that DIY lashes are largely manufactured in China, you’ll find many suppliers offering a wide variety of PBT-based options. Always request samples to assess the quality for yourself. This is something Sophie, with her eye for quality, would definitely do.

Do Wholesale Lash Manufacturers Provide Private Label or OEM/ODM Services?

Dreaming of seeing your own brand name on those DIY lash kits? This is where private labeling and OEM/ODM services come into play, and they are very common in this industry.

Yes, most reputable wholesale lash manufacturers, especially those in major production hubs like China, extensively offer private label (branding existing products) and OEM/ODM (Original Equipment/Design Manufacturer for custom products) services. [1, 5]

This is a core part of our business at UBLash. We help brands create their unique identity in the market. Offering these services allows businesses like yours to build brand loyalty and differentiate themselves. [1]

Understanding Your Branding Options:

- Private Label:

- What it is: You select from the manufacturer’s existing range of DIY lash styles and packaging templates. They then produce these products with your brand name, logo, and chosen design elements on the packaging. [5]

- Pros: Faster to market, lower development costs, proven product designs.

- Cons: Less product differentiation, as other brands might use similar base products.

- Best for: New brands, those wanting to test the market quickly, or brands focusing on marketing rather than product innovation.

- OEM (Original Equipment Manufacturer):

- What it is: You provide the detailed specifications and design for a DIY lash product, and the manufacturer produces it exclusively for you. You own the design.

- Pros: Unique product, full control over specifications, strong brand differentiation.

- Cons: Higher development costs, longer lead times, potentially higher MOQs.

- ODM (Original Design Manufacturer):

- What it is: A hybrid approach. The manufacturer might have existing base designs or concepts for DIY lashes that they can then modify or customize according to your specific requirements (e.g., unique cluster arrangements, specific fiber combinations, new packaging ideas).

- Pros: Faster than full OEM but offers more customization than basic private label. [3] Leverages manufacturer’s expertise.

- Cons: Shared IP on the base design, costs can vary.

| Service Type | Product Origin | Customization Level | Your Involvement | UBLash Offers |

|---|---|---|---|---|

| Private Label | Manufacturer’s Stock [5] | Low (Branding, Packaging) [1, 5] | Select & Brand | Yes |

| OEM | Your Design | High (Full Product Specification) | Design & Specify | Yes |

| ODM | Manufacturer’s Base + Your Input | Medium to High (Co-creation) [3] | Collaborate & Customize | Yes |

Many Chinese factories are incredibly adept at all these services, offering a vast array of existing DIY lash styles you can private label, or working with you to create something totally new. The key is clear communication about your vision and requirements.

What Is the Average Lead Time for Production and Shipping from Lash Supply Factories?

Once you’ve placed your order, how long will you typically wait? Understanding lead times is essential for planning your inventory and launch dates.

The average lead time for production and shipping from lash supply factories, particularly in China, can range from 3-4 weeks. Production might take 2-3 weeks, and shipping (depending on method) can take an additional 1-2 weeks. This varies greatly based on order size, customization, and factory workload.

I always advise clients to factor in potential delays, especially around peak seasons or holidays. For UBLash, clear communication about timelines is a priority to help our B2B customers plan effectively.

Factors Influencing Lead Times:

- Order Complexity & Customization: Standard, in-stock DIY lash styles with simple packaging will have shorter production times. Highly customized lashes, unique packaging, or new product developments will take longer due to design, sampling, and retooling.

- Order Size: Larger orders naturally take more time to produce than smaller ones. However, very small orders might sometimes take longer if they have to be fit into larger production runs.

- Component Sourcing: If your DIY kits require specific, non-standard components (e.g., a unique applicator tool, special adhesive tubes, custom-printed inserts), the factory might need extra time to source these from their own suppliers.

- Factory’s Current Workload: A busy factory with many orders in its queue will have longer lead times. It’s good to ask about their current capacity.

- Quality Control & Inspection: Thorough QC takes time but is crucial. Don’t rush this step.

- Shipping Method:

- Air Freight: Faster (typically 3-10 days) but more expensive. Good for smaller, urgent orders.

- Sea Freight: Slower (typically 3-6 weeks, depending on destination) but more cost-effective for bulk shipments.

- Express Couriers (DHL, FedEx, UPS): Fastest (2-7 days), most expensive, often used for samples or small, high-value orders.

- Time of Year: Production can slow down or halt during major holidays like Chinese New Year. Plan well ahead if ordering around these times.

| Stage | Typical Duration | Influencing Factors |

|---|---|---|

| Pre-Production | 1-2 Weeks | Sample approval, deposit payment, material confirmation |

| Production | 2-5 Weeks | Order size, complexity, customization, factory schedule |

| Quality Control | 2-5 Days | Thoroughness of inspection protocols |

| Packaging | 3-7 Days | Complexity of packaging, labeling |

| Shipping | 1-6 Weeks | Shipping method chosen, customs clearance, destination |

For someone like Sophie in Canada, shipping from China will be a significant part of the lead time. It’s wise to build a buffer into your timeline and discuss shipping options and Incoterms clearly with your supplier.

What Are the Differences Between Buying from a Manufacturer Versus a Distributor for DIY Lash Supplies?

You have choices: go direct to the factory or work with a middleman. Which path is better for your wholesale DIY lash supply needs?

Buying directly from a DIY lash manufacturer (like many in China) typically offers lower prices, greater customization options [3], and direct communication, but often requires higher MOQs. A distributor offers lower MOQs, faster local shipping (if domestic), but higher unit prices and less customization.

At UBLash, we operate as a manufacturer offering private label and OEM/ODM, so we often work directly with brands. However, we also understand that some new businesses might start with distributors before they can meet factory MOQs.

Manufacturer vs. Distributor: A Closer Look

Buying Direct from a Manufacturer (e.g., UBLash, other Chinese factories):

- Pros:

- Lower Prices: Cutting out the middleman usually means better per-unit costs, improving your profit margins. [6]

- Greater Customization: Direct access to the production facility means more control over product design, materials, and packaging. [3, 5] Ideal for private label, OEM/ODM.

- Direct Communication: Fewer misinterpretations, faster problem-solving.

- Full Product Range: Access to all their available styles, including new innovations. [2, 6]

- Insight into Production: Potential for factory visits (important for someone like Sophie who values quality inspection).

- Cons:

- Higher MOQs: Factories often require larger order volumes. [3]

- Longer Lead Times: Especially if manufacturing overseas (e.g., from China to Canada).

- Logistics & Importation: You’ll likely need to handle international shipping, customs, duties, and taxes.

- Communication Barriers: Potential language or cultural differences if not experienced.

Buying from a Distributor:

- Pros:

- Lower MOQs: Distributors break bulk, making it easier for small businesses to start.

- Faster Shipping (Often): If the distributor is local or regional, you can get products more quickly.

- Simplified Logistics: Usually handles importation and may offer simpler shipping terms.

- Consolidated Orders: Can buy smaller quantities of various products from different brands they carry.

- Cons:

- Higher Prices: Distributor adds their markup.

- Limited Customization: Usually only offer standard products; private labeling options might be restricted or more expensive. [1]

- Less Control: Indirect communication with the actual manufacturer.

- Potentially Limited Range: May not carry the full range of a manufacturer’s products. [2, 6]

| Feature | Manufacturer Direct | Distributor |

|---|---|---|

| Price | Lower | Higher |

| MOQ | Higher [3] | Lower |

| Customization | High [3, 5] | Low to None [1] |

| Lead Time | Longer (production + international shipping) | Shorter (if stocked locally) |

| Communication | Direct | Indirect (through distributor) |

| Product Range | Full [2, 6] | Limited to what they stock [2, 6] |

| Logistics | More complex (you handle import) | Simpler (often inclusive) |

For a business owner like Sophie aiming to build her own distinct brand with specific quality and design preferences, and who is willing to manage imports from China, dealing directly with a manufacturer like UBLash is generally the more advantageous route for DIY lashes.

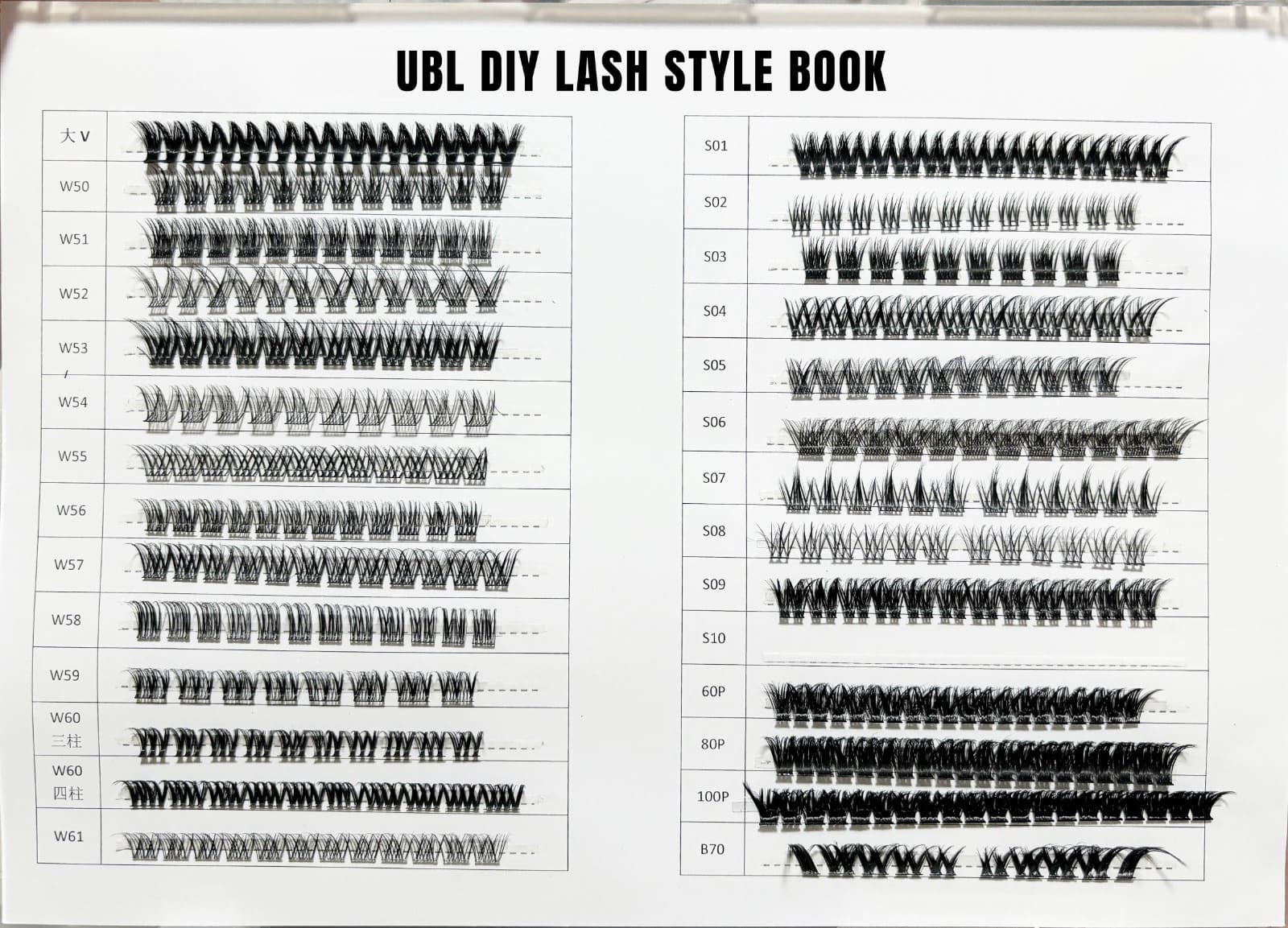

Can Wholesale Lash Manufacturers Customize Lash Styles, Lengths, and Packaging?

Want your DIY lash kits to stand out with unique styles and branding? Customization is key, and thankfully, it’s a big part of what wholesale manufacturers offer.

Yes, absolutely. Wholesale lash manufacturers, especially those specializing in OEM/ODM like many in China, are highly capable of customizing lash styles, lengths, curls, thicknesses, band types, and all aspects of packaging to meet your brand’s specific requirements. [3, 5]

This is where the fun begins for brand creators! At UBLash, we thrive on collaborating with clients to bring their unique visions for DIY lash kits to life. From specific lash segment designs to the unboxing experience, customization is central.

Areas for DIY Lash Customization:

- Lash Styles & Mapping:

- Cluster Design: You can specify the number of fibers per cluster, the arrangement (e.g., criss-cross, straight, flared), and the overall shape of each segment. China’s manufacturing capabilities mean many DIY styles are already available as a base, or new ones can be developed.

- Length Variation: Create kits with graduated lengths for a cat-eye or doll-eye effect, or single-length kits.

- Curls: Common curls (J, B, C, CC, D, L, M, etc.) are available, and you can specify these for your DIY segments.

- Thickness/Diameter: Choose fiber thickness (e.g., 0.03mm, 0.05mm, 0.07mm, 0.10mm) to achieve different levels of volume and naturalness.

- Lash Bands:

- Clear Bands: Offer an invisible, seamless look.

- Black Bands: Can provide an eyeliner effect.

- Segmented Bands: Most DIY lashes are on tiny, pre-cut band segments for under-lash or over-lash application.

- Materials & Finish: Specify PBT quality, faux mink or silk finish, matte or slight sheen.

- Packaging: This is a huge area for branding. [1, 5]

- Box Type & Material: Sliding boxes, magnetic closure boxes, window boxes, eco-friendly materials.

- Printing & Design: Your logo, brand colors, artwork, instructions, ingredient lists. [5]

- Inserts & Trays: Custom trays to hold lash segments, bond, seal, and remover tools.

- Accessory Tools: Options to include branded tweezers/applicators.

| Customization Area | Examples | Importance for Branding |

|---|---|---|

| Lash Design | Unique cluster shapes, mixed lengths/curls, specific fiber patterns | Product differentiation, signature look |

| Lash Dimensions | Precise lengths (e.g., 8mm-16mm), curls (C, D, etc.), thicknesses (0.07mm) | Catering to diverse eye shapes & styles |

| Packaging Box | Custom shape, material, finish (matte/gloss), full-color printing [5] | Brand recognition, perceived value |

| Inner Tray | Layout of lash segments, wells for bond/seal, spot for applicator | User experience, product presentation |

| Branding Elements | Logo, brand story, instructions, social media handles on packaging [1, 5] | Brand identity, customer engagement |

The ability to customize is a major reason why brands choose to work directly with manufacturers. You can truly create a product that reflects your brand’s unique selling proposition. With the insight that DIY lashes are largely made in China, you’ll find an abundance of factories ready to help you customize.

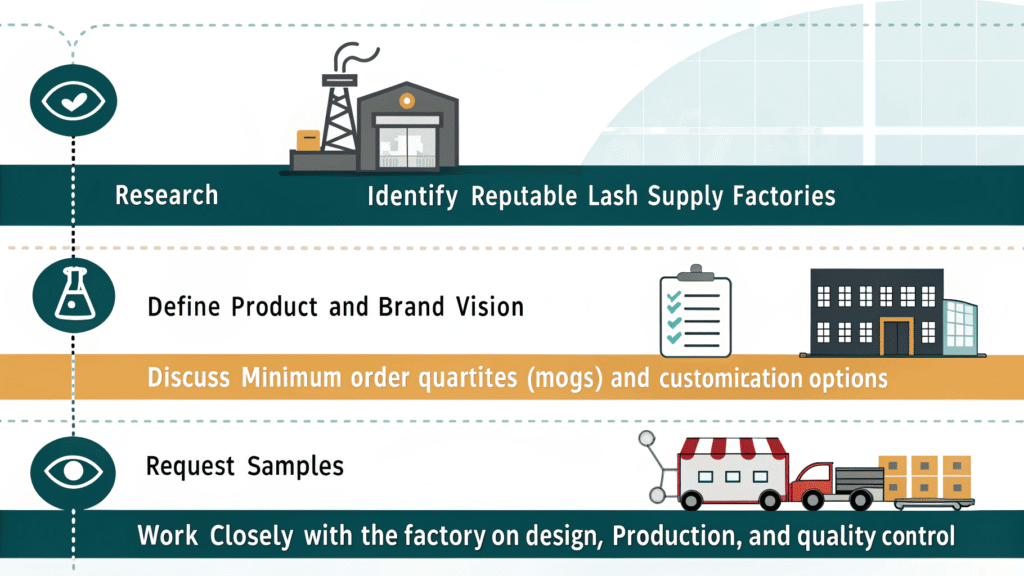

How Can I Start My Own Private Label Line with a Lash Supply Factory?

Ready to take the plunge and create your very own private label DIY lash line? It’s an exciting step, and here’s how you can approach it with a lash supply factory.

To start your private label line, research and identify reputable lash supply factories (many in China), clearly define your product and brand vision, discuss MOQs and customization options [3], request samples, and then work closely with the factory on design, production, and quality control. [1]

Helping new brands launch is something we do often at UBLash. It’s a journey, but with a clear plan and a good manufacturing partner, it’s very achievable. Here’s a more detailed look at the steps:

Steps to Launch Your Private Label DIY Lash Line:

- Market Research & Brand Definition:

- Identify Your Niche: Who is your target customer for DIY lashes? What kind of styles do they prefer (natural, dramatic, wispy)? What’s your unique selling proposition (e.g., ultra-soft, easiest application, vegan, specific aesthetic)?

- Competitor Analysis: See what’s already on the market. How can you differentiate?

- Brand Identity: Develop your brand name, logo, color palette, and overall brand voice. [1]

- Find Potential Factories/Suppliers:

- Online Platforms: Alibaba, Made-in-China, DHGate (be sure to vet suppliers carefully).

- Trade Shows: (If applicable and accessible) Industry trade shows are great for meeting suppliers.

- Referrals/Networking: Ask others in the industry.

- Direct Search: Look for lash manufacturers like UBLash who explicitly offer private label/OEM. [1]

- Initial Contact & Vetting:

- Introduce Your Brand: Clearly explain your concept and what you’re looking for.

- Inquire about MOQs, Pricing, Lead Times. [3]

- *Ask about their experience with private labeling and your target market (e.g., North America, Europe).

- Request Company Certifications: (e.g., ISO for quality management).

- Define Product Specifications & Request Samples:

- Be Specific: Detail the DIY lash styles (lengths, curls, materials), packaging ideas, and any included accessories (bond, seal, remover, applicator). [3]

- ALWAYS Order Samples: This is critical to assess quality before committing to a bulk order. Test them yourself.

- Design & Packaging Development:

- Work with the Factory’s Designers or Your Own: Provide your logo and brand guidelines for packaging mock-ups. [5]

- Approve All Designs: Ensure every detail, from box layout to insert text, is perfect.

- Negotiate Terms & Place Order:

- Finalize Price, Payment Terms, Incoterms (shipping terms), and Production Schedule.

- Place Your Deposit: Most factories require an upfront deposit (often 30-50%).

- Production & Quality Control:

- Stay in Communication: Get updates on production progress.

- Arrange for Quality Inspection: Either visit the factory (if feasible), hire a third-party inspection service, or have a very clear agreement on internal QC processes and defect rates. This is crucial for Sophie’s focus on quality.

- Shipping & Logistics:

- Coordinate Shipping: Choose your freight method and handle customs clearance (or work with a freight forwarder).

- Receive & Launch!

| Step | Key Action | Tip for Success |

|---|---|---|

| 1. Research & Branding | Define niche, USP, brand identity. | Know your customer inside out. |

| 2. Find Suppliers | Use online platforms, trade shows, referrals. Look for OEM/Private Label specialists. | Vet suppliers thoroughly; don’t just go for the cheapest. |

| 3. Initial Contact | Introduce brand, ask about MOQs [3], lead times, experience. | Be professional and clear in your communications. |

| 4. Samples | Specify desired DIY lash styles, materials. Order and test samples. | Never skip samples! This is your quality check. |

| 5. Design | Finalize packaging artwork with your branding. [1, 5] | Ensure packaging is functional, attractive, and compliant. |

| 6. Order | Negotiate terms, place deposit. | Get everything in writing in a clear contract/Proforma Invoice. |

| 7. Production & QC | Monitor progress, implement quality control checks. | Don’t compromise on quality inspection. |

| 8. Shipping | Arrange logistics, customs. | Understand Incoterms and factor in all shipping costs. |

Starting a private label DIY lash line is an investment of time and resources, but by partnering with the right factory, especially skilled ones in China, you can create high-quality, customized products that resonate with your target audience.

Conclusion

Sourcing wholesale DIY lashes successfully hinges on finding reliable manufacturers, understanding customization options [3, 5], MOQs [3], and managing logistics, enabling you to build a thriving private label brand.

-

Explore the advantages of PBT in lash materials to understand why it’s a top choice for DIY lashes. ↩ ↩

-

Learn about the production and benefits of faux mink lashes for a luxurious and ethical lash experience. ↩ ↩

-

Learning about packaging’s effect on MOQ can help you choose the right packaging solutions that align with your budget and production needs. ↩

Fanny

Lash Technician

Hi, I’m Fanny, the author of this post.

Over the past 5 years, we have assisted numerous lash salons and technicians across 20 countries to build their lash brand and grow their businesses with high-quality lash extension products.

If you have any questions or need assistance, feel free to reach out for a free consultation or to discuss tailored solutions for your business needs.

More Interesting Posts

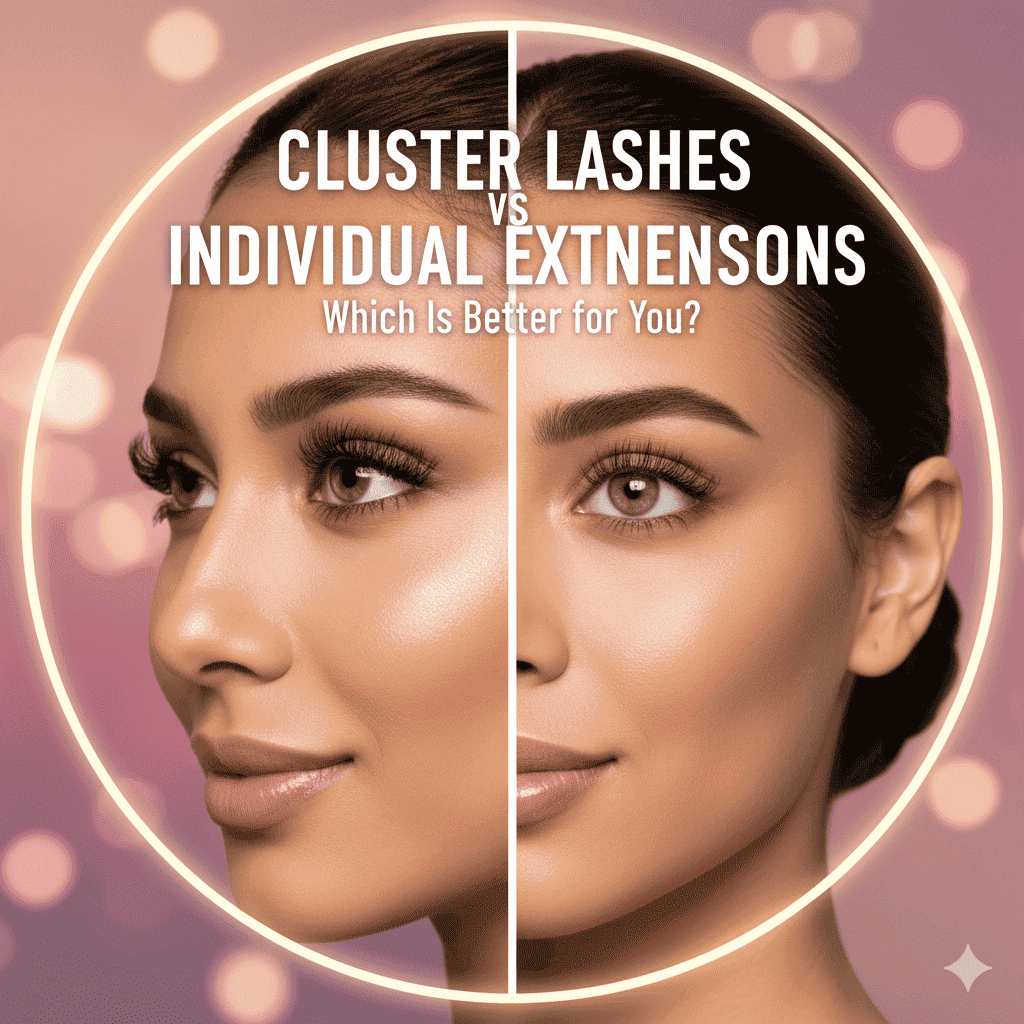

Cluster Lashes vs Individual Extensions: Which Is Better for You?

Lash Extension Supply Business Opportunities: Wholesale Distribution Guide

When to Use L Curl Lashes: The Perfect Choice for Hooded and Droopy Eyes?