Are you tired of high MOQ requirements that strain your budget? Negotiating favorable terms is essential for profitable bulk lash purchasing.

Successful MOQ negotiation involves understanding supplier flexibility, building relationships, and demonstrating long-term partnership potential to unlock better pricing and terms. Effective negotiation can reduce costs by 15-30%.

Understanding the art of MOQ negotiation separates successful lash businesses from struggling ones. Let me share proven strategies that have worked for hundreds of our clients.

What Exactly is MOQ and Why Do Suppliers Set Minimum Order Quantities?

Many lash business owners misunderstand MOQ requirements, leading to poor purchasing decisions and strained supplier relationships.

MOQ stands for Minimum Order Quantity – the smallest amount a supplier will produce or sell, set to ensure production efficiency and profitability while covering fixed costs. Suppliers need volume to justify production runs.

Understanding MOQ Fundamentals

| MOQ Component | Purpose | Supplier Perspective | Buyer Impact |

|---|---|---|---|

| Production Costs | Cover setup expenses | Machine setup, labor allocation | Higher MOQ = lower per-unit cost |

| Material Sourcing | Minimum material purchases | Bulk material discounts | Access to better material pricing |

| Labor Efficiency | Optimize worker productivity | Full production runs | Consistent quality control |

| Shipping Economics | Cost-effective logistics | Container/truck optimization | Reduced shipping costs per unit |

| Profit Margin | Maintain business viability | Cover overhead expenses | Better pricing at higher volumes |

MOQ requirements exist for practical business reasons that benefit both suppliers and buyers. Production setup costs represent a significant portion of overall expenses. Each production run requires machine calibration, material preparation, and labor allocation. These fixed costs remain the same whether producing 100 units or 10,000 units. Suppliers calculate MOQ to ensure these setup costs don’t disproportionately impact per-unit pricing. Material sourcing also drives MOQ decisions. Raw materials like premium synthetic fibers, medical-grade adhesives, and packaging materials often have their own minimum purchase requirements. Buying in larger quantities allows suppliers to secure better material pricing, which they can pass along to buyers. Labor efficiency improves with larger production runs as workers become more proficient with consistent tasks. Shipping economics favor larger orders too – filling containers or truckloads reduces transportation costs per unit. Profit margins must cover not just production but also research, development, quality control, and business overhead. At UBLash, we maintain transparent MOQ policies that balance our operational needs with client affordability.

How Can You Effectively Negotiate Lower MOQ Requirements?

Many buyers accept MOQ terms without negotiation, missing significant cost-saving opportunities through strategic discussion.

Effective MOQ negotiation involves demonstrating long-term value, offering flexible payment terms, and proposing creative solutions like mixed product orders to meet minimums. Preparation and relationship-building are key success factors.

MOQ Negotiation Strategy Framework

| Negotiation Tactic | Implementation | Supplier Benefit | Your Advantage |

|---|---|---|---|

| Relationship Building | Regular communication, visits | Loyal customer retention | Preferred pricing, flexibility |

| Payment Terms | Advance payments, larger deposits | Improved cash flow | Lower MOQ acceptance |

| Product Mixing | Combine different products | Same production efficiency | Meet MOQ with variety |

| Growth Projections | Share business expansion plans | Future volume commitment | Graduated MOQ reduction |

| Seasonal Flexibility | Off-peak ordering | Production smoothing | Better terms during slow periods |

| Quality Partnership | Provide detailed feedback | Product improvement data | Negotiation leverage |

Successful MOQ negotiation begins long before discussing numbers. Building strong supplier relationships creates foundation for flexibility. Regular communication, factory visits when possible, and treating suppliers as partners rather than vendors establishes trust. Suppliers are more likely to accommodate reasonable MOQ adjustments for trusted partners who demonstrate commitment. Payment terms offer powerful negotiation leverage. Offering larger deposits or advance payments improves supplier cash flow, making them more receptive to lower MOQ requests. Creative product mixing represents another effective strategy. Instead of ordering large quantities of single products, propose combining multiple products to reach the overall MOQ threshold. This approach maintains the supplier’s production efficiency while giving you product diversity. Sharing realistic business growth projections demonstrates your potential as a long-term customer. Suppliers may accept lower initial MOQs in anticipation of future volume increases. Timing your orders during supplier off-peak periods can also yield better terms. Providing detailed product feedback and quality improvement suggestions positions you as a valuable partner invested in mutual success. At UBLash, we appreciate clients who approach negotiations as collaborative problem-solving rather than transactional bargaining.

What Volume Discount Structures Should You Expect from Lash Suppliers?

Understanding standard discount tiers helps you benchmark offers and negotiate favorable pricing as your order volume increases.

Standard volume discounts typically follow tiered structures: 5-10% for orders 2x MOQ, 10-15% for 3-5x MOQ, and 15-25% for orders exceeding 5x MOQ, with custom pricing for strategic partners. Discounts reflect reduced per-unit production costs.

Volume Discount Expectation Guide

| Order Volume Multiple | Typical Discount Range | Qualification Requirements | Additional Benefits |

|---|---|---|---|

| 1-2x MOQ | 0-5% discount | Standard pricing | Basic terms |

| 2-3x MOQ | 5-10% discount | Consistent ordering | Priority processing |

| 3-5x MOQ | 10-15% discount | Quarterly commitments | Extended payment terms |

| 5-10x MOQ | 15-20% discount | Annual contracts | Custom packaging options |

| 10x+ MOQ | 20-25% discount | Strategic partnership | Dedicated account management |

| Custom Projects | Negotiated pricing | Exclusive arrangements | Product development input |

Volume discount structures vary by supplier but generally follow predictable patterns based on order quantity multiples of the base MOQ. For orders just meeting MOQ requirements, expect standard pricing with minimal discounts. Once you consistently order 2-3 times the MOQ, 5-10% discounts become reasonable as suppliers benefit from production efficiencies. At 3-5 times MOQ, discounts typically increase to 10-15% range, often accompanied by benefits like priority production scheduling and extended payment terms. Orders exceeding 5 times MOQ qualify for 15-20% discounts and may include value-added services like custom packaging or minor product modifications. Strategic partnerships involving 10x MOQ or annual contracts can secure 20-25% discounts along with dedicated account management and input on product development. The key is understanding that discounts reflect actual cost savings from larger production runs – material procurement discounts, reduced changeover time, optimized labor allocation, and shipping efficiencies. At UBLash, we offer transparent tiered pricing that rewards clients for volume commitments while maintaining fair margins that support continuous quality improvement.

How Do Payment Terms Affect Your MOQ and Pricing Negotiations?

Payment structure significantly influences supplier willingness to adjust MOQ requirements and offer better pricing terms.

Advance payments, letters of credit, and consistent payment history build supplier confidence, enabling MOQ reductions of 15-30% and additional 2-5% price discounts. Payment reliability reduces supplier risk.

Payment Term Impact Analysis

| Payment Method | Supplier Risk | Your Negotiation Power | Typical MOQ/Pricing Impact |

|---|---|---|---|

| 100% Advance | Lowest risk | Highest leverage | 20-30% MOQ reduction possible |

| 50% Deposit | Moderate risk | Good leverage | 15-25% MOQ improvement |

| Letter of Credit | Bank guaranteed | Strong position | 10-20% better terms |

| Net 30 Terms | Higher risk | Requires history | 5-15% with established relationship |

| Consistent Payments | Builds trust | Growing influence | Gradual improvements over time |

| Late Payments | Damages trust | Reduces flexibility | Higher MOQ, stricter terms |

Payment terms directly correlate with supplier risk assessment, which influences their MOQ and pricing flexibility. Suppliers face significant financial exposure when producing custom orders – they invest in materials, labor, and production capacity before receiving payment. Advance payments substantially reduce this risk, making suppliers more willing to accommodate lower MOQ requests. A 100% advance payment demonstrates strong commitment and financial stability, often enabling 20-30% MOQ reductions and additional price discounts. Fifty percent deposits with balance before shipment also provide good negotiation leverage, typically resulting in 15-25% MOQ improvements. Letters of credit from reputable banks offer suppliers payment guarantee, positioning you for 10-20% better terms. Net 30 payment terms require established relationships and consistent payment history but can yield 5-15% improvements over time. The most powerful payment-related strategy is consistent, timely payments that build trust and demonstrate reliability. This track record creates negotiation capital for future orders. Conversely, late payments damage supplier relationships and typically result in higher MOQs and stricter terms. At UBLash, we work with clients to establish payment structures that balance their cash flow needs with our risk management requirements.

What Quality Assurance Measures Should You Expect with Bulk Orders?

Larger orders warrant enhanced quality control processes to protect your investment and maintain product consistency.

Reputable suppliers provide pre-production samples, during-production inspections, and pre-shipment quality checks, with comprehensive documentation and replacement guarantees for defective products. Quality assurance scales with order volume.

Bulk Order Quality Assurance Standards

| Quality Stage | Standard Procedures | Documentation Provided | Your Rights & Recourse |

|---|---|---|---|

| Pre-Production | Approval samples, material testing | Sample reports, material certificates | Adjust specifications before mass production |

| During Production | Random inspections, process audits | In-process quality records | Address issues early, minimize waste |

| Pre-Shipment | Final inspection, functionality tests | Inspection reports, compliance certificates | Reject non-conforming shipments |

| Packaging | Label accuracy, package integrity | Packing lists, shipment photos | Ensure brand representation |

| Documentation | Compliance certificates, test reports | Full quality dossier | Regulatory compliance evidence |

| After-Sales | Defective product replacement | Return authorization procedures | Product guarantee fulfillment |

Quality assurance should intensify proportionally with order volume. For significant bulk purchases, expect comprehensive quality control processes at multiple stages. Pre-production quality begins with approval samples that exactly match your specifications. Reputable suppliers provide detailed sample reports and material certification documentation. During production, random inspections and process audits ensure consistency across the entire order volume. These intermediate checks allow for early issue identification and correction before completing full production runs. Pre-shipment inspection represents the most critical quality stage, involving thorough examination of finished products against agreed specifications. Comprehensive inspection reports should document testing methods, acceptance criteria, and results. Packaging quality matters equally for bulk orders – verify label accuracy, package integrity, and proper handling to maintain product condition during transit. Complete documentation packages should include compliance certificates, test reports, and all necessary regulatory documentation for your market. After-sales quality assurance includes clear procedures for addressing defective products, typically involving replacement of non-conforming items. At UBLash, we implement rigorous multi-stage quality control that escalates with order volume to ensure every product meets exacting standards.

How Can You Build Strategic Supplier Relationships for Better Terms?

Long-term supplier partnerships yield significant advantages beyond immediate pricing, including preferential treatment and collaborative innovation.

Strategic relationships develop through consistent communication, fair treatment, transparent feedback, and demonstrated growth potential, leading to customized terms, exclusive products, and priority access. Partnership mindset creates mutual value.

Supplier Relationship Development Strategy

| Relationship Level | Interaction Frequency | Benefits Unlocked | Investment Required |

|---|---|---|---|

| Transactional | Order-by-order basis | Standard terms | Minimal investment |

| Developing | Quarterly communications | Moderate flexibility | Regular engagement |

| Established | Monthly updates, visits | Custom terms, better pricing | Time, relationship building |

| Strategic | Bi-weekly collaboration | Exclusive products, joint development | Significant commitment |

| Partnership | Integrated operations | Co-branding, equity opportunities | Deep business integration |

| Innovation | Continuous development | Market leadership position | Shared R&D investment |

Building strategic supplier relationships transforms transactional interactions into valuable partnerships that deliver compounding benefits. The journey begins with moving beyond order-by-order transactions to regular, meaningful communication. Quarterly business reviews, factory visits when feasible, and transparent sharing of your business challenges and goals establish foundation for partnership. As relationships develop into established status through monthly updates and consistent order volumes, suppliers typically offer custom terms, better pricing, and priority production scheduling. Strategic relationships involve bi-weekly collaboration, shared market intelligence, and co-development of exclusive products tailored to your specific market needs. Partnership-level relationships feature integrated operations, potential co-branding opportunities, and even equity participation in exceptional cases. The highest level, innovation partnership, involves continuous joint development efforts that position both companies as market leaders. Each relationship level requires corresponding investment in time, communication, and business transparency. The returns include not just better pricing and terms but also access to new product developments, market insights, and operational efficiencies. At UBLash, we prioritize developing strategic relationships with clients who share our commitment to quality, innovation, and mutual growth.

What Logistics Considerations Impact Bulk Lash Extension Purchases?

Shipping and logistics represent significant cost and risk factors in bulk purchasing that require careful planning and negotiation.

Bulk shipping options include sea freight for cost efficiency, air freight for speed, and hybrid solutions, with factors like incoterms, insurance, and customs clearance affecting total landed cost. Logistics planning prevents unexpected expenses.

Bulk Purchase Logistics Planning

| Logistics Factor | Cost Impact | Time Consideration | Risk Management |

|---|---|---|---|

| Shipping Method | Sea: 60-80% savings vs air | Sea: 30-45 days, Air: 5-10 days | Insurance requirements vary |

| Incoterms | Determines cost responsibility | Affects customs clearance process | Risk transfer points defined |

| Packaging | Affects volumetric weight | Influences handling efficiency | Product protection level |

| Customs | Duties, taxes, brokerage fees | Clearance time varies by country | Documentation accuracy critical |

| Insurance | 1-3% of shipment value | Claim processing time | Coverage limits and exclusions |

| Warehousing | Storage costs, handling fees | Inventory turnover efficiency | Security, climate control |

Logistics planning significantly impacts the total cost and success of bulk lash extension purchases. Shipping method selection represents the most substantial cost variable. Sea freight typically costs 60-80% less than air freight but requires 30-45 days transit time versus 5-10 days for air. For non-urgent bulk orders, sea freight offers substantial savings, while air freight suits time-sensitive shipments. Incoterms (International Commercial Terms) define cost responsibility and risk transfer points between buyer and supplier. Common incoterms like FOB (Free On Board) and EXW (Ex Works) place different responsibilities on each party. Packaging considerations affect both cost and product safety. Efficient packaging minimizes volumetric weight charges while ensuring adequate protection during extended transit. Customs clearance involves duties, taxes, and brokerage fees that vary by destination country. Accurate documentation prevents delays and penalties. Insurance typically costs 1-3% of shipment value but provides crucial protection against loss or damage. Understanding coverage limits and exclusions is essential. For large orders, warehousing arrangements may be necessary, involving storage costs and inventory management considerations. At UBLash, we assist clients with comprehensive logistics planning that optimizes cost, time, and risk factors based on their specific needs.

Conclusion

Mastering MOQ negotiation and understanding volume discounts transforms bulk lash purchasing from a cost center to competitive advantage through strategic supplier relationships and smart logistics planning.

Fanny

Lash Technician

Hi, I’m Fanny, the author of this post.

Over the past 5 years, we have assisted numerous lash salons and technicians across 20 countries to build their lash brand and grow their businesses with high-quality lash extension products.

If you have any questions or need assistance, feel free to reach out for a free consultation or to discuss tailored solutions for your business needs.

More Interesting Posts

Wholesale vs Retail Lash Supplies: What’s the Real Cost & Profit Difference?

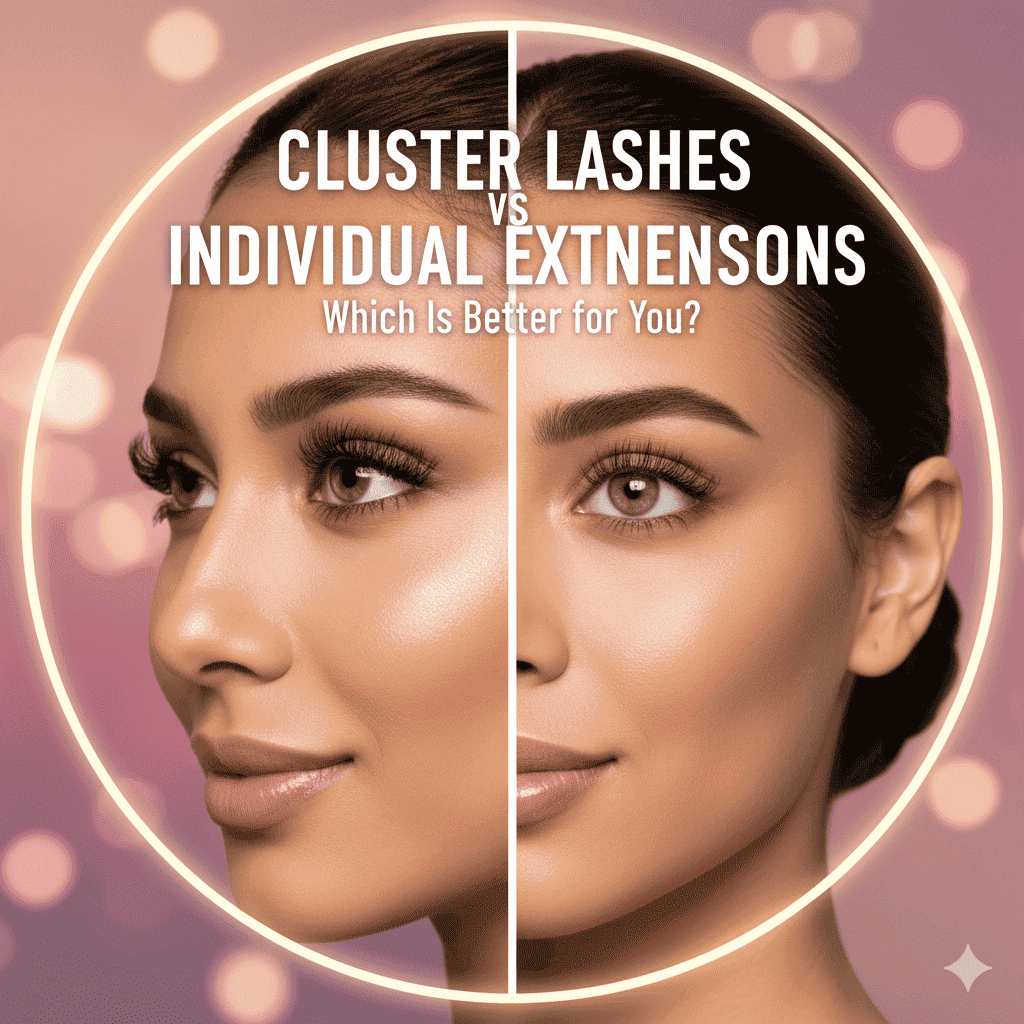

Cluster Lashes vs Individual Extensions: Which Is Better for You?

Lash Extension Supply Business Opportunities: Wholesale Distribution Guide