Staring at adhesive that won’t set while production deadlines loom? Your environment might be sabotaging your cure times without you realizing it.

Fast-curing adhesives (cyanoacrylates, UV-cures) set in seconds/minutes but require specific conditions, while slow-curing adhesives (epoxies, some acrylics) offer stronger bonds and better gap-filling but take hours/days. Choose based on your temperature, humidity, and application complexity [2][3][4].

At UBLash, we’ve helped countless lash technicians navigate adhesive selection. The right choice isn’t about speed alone—it’s about matching chemistry to your working conditions.

Why Does Cure Time Vary So Dramatically Between Environments?

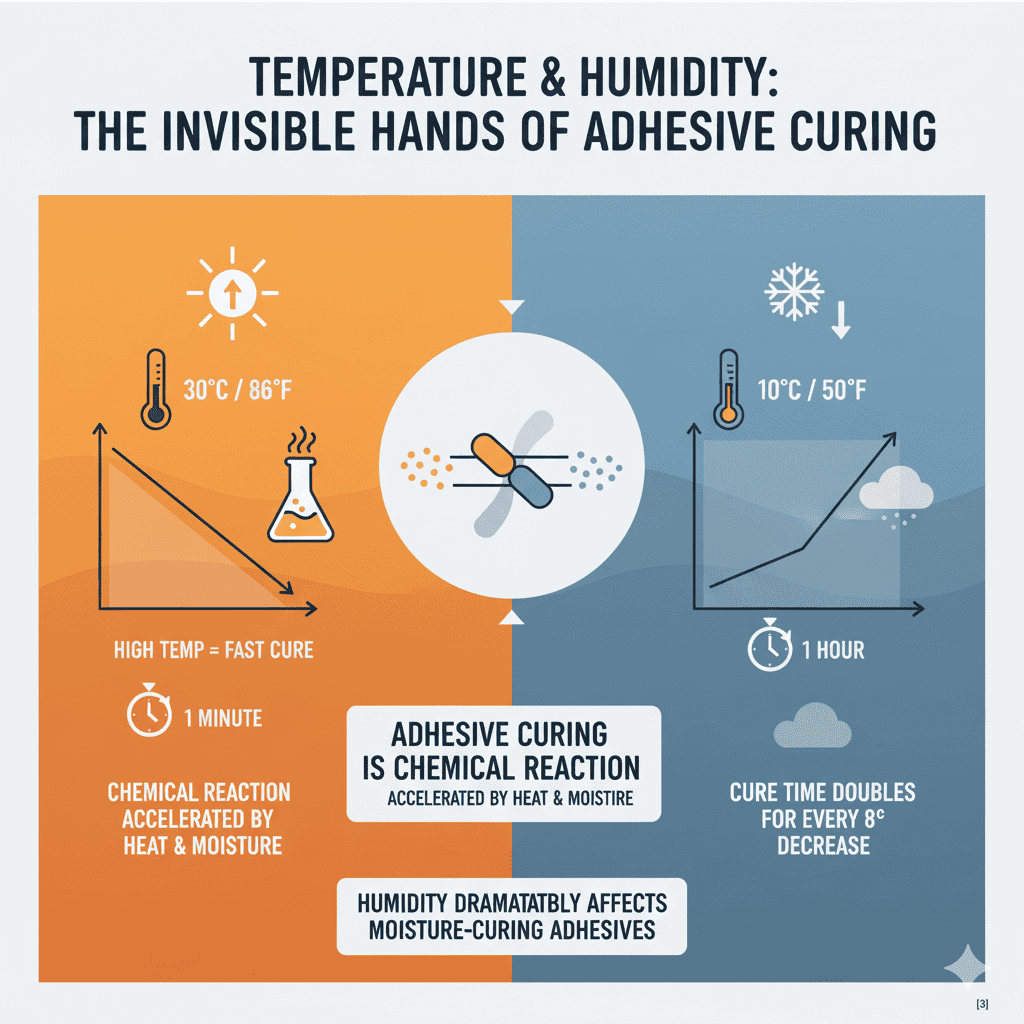

Notice how the same adhesive performs differently in summer versus winter? Temperature and humidity are the invisible hands controlling your cure times.

Adhesive curing is a chemical reaction accelerated by heat and moisture. For every 8°C temperature increase, cure time halves; for every 8°C decrease, it doubles. Humidity affects moisture-curing adhesives even more dramatically [3].

The Science Behind Environmental Impact

Three environmental factors dictate cure speed:

-

Temperature Dominance

- Governs molecular movement and reaction rates

- Ideal range: 15-25°C for most adhesives

- Below 5°C drastically slows curing [3]

-

Humidity Influence

- Critical for moisture-curing systems (cyanoacrylates, MS polymers)

- Accelerates curing through water molecule interaction

- Less impact on two-component systems [3]

-

Application Variables

- Substrate temperature (often overlooked)

- Adhesive volume (thicker layers cure slower)

- Air circulation affects moisture exposure [2][3]

Performance comparison by environment:

| Environment | Fast-Cure Performance | Slow-Cure Performance | Risk Factors |

|---|---|---|---|

| Hot/Dry (25-30°C, <30% RH) | Excellent | May cure too fast | Reduced working time, heat buildup |

| Ideal (20°C, 50% RH) | Predictable | Consistent | Minimal issues |

| Cold/Damp (5-10°C, >70% RH) | Very poor | Slow but functional | Extended cure times, weak bonds |

| Variable (seasons) | Unpredictable | More stable | Requires constant adjustment [3] |

Pro Tip: Measure both room temperature and substrate temperature—they often differ significantly [3].

When Should You Choose Fast-Curing Adhesives?

That tempting instant bond might solve immediate frustration but create long-term problems if misapplied.

Fast-curing adhesives1 excel in controlled environments (20-25°C, 40-60% RH), high-volume production lines, and applications requiring quick handling strength. They’re ideal for small bonds, quick repairs, and automated processes [2][4].

Ideal Fast-Cure Applications

- Assembly lines with rapid cycle times

- Automated dispensing systems

- High-volume manufacturing [4]

2. Specific Bond Types

- Small surface areas

- Thin bond lines

- Materials with low thermal mass [2]

3. Environmental Conditions

- Climate-controlled facilities

- Consistent temperature/humidity

- Indoor applications [3]

4. Technical Advantages

- Immediate fixture strength

- Reduced jigging time

- Faster throughput [4]

Critical limitations:

| Fast-Cure Type | Working Time | Environmental Sensitivity | Best For |

|---|---|---|---|

| Cyanoacrylates | 10-60 seconds | High humidity required | Small plastic bonds |

| UV-Curable | Unlimited until exposed | UV light access needed | Electronics, clear materials |

| Rapid Acrylics | 2-5 minutes | Temperature sensitive | Metal/plastic assemblies [4] |

UBLash technicians report 90% success with fast-cure adhesives in climate-controlled lash studios [3].

When Do Slow-Curing Adhesives Actually Work Better?

That extended wait time might seem inefficient, but it often produces stronger, more reliable bonds.

Slow-curing adhesives outperform in variable environments, large bond areas, and complex assemblies. They tolerate temperature fluctuations better, provide superior final strength, and allow more working time for precise placement [2][3].

Slow-Cure Advantage Scenarios

1. Environmental Challenges

- Uncontrolled temperatures

- Low humidity conditions

- Outdoor or variable environments [3]

2. Complex Applications

- Large surface areas

- Thick bond lines

- Gap-filling requirements [2]

3. Quality Considerations

- Maximum bond strength development

- Reduced internal stresses

- Better durability long-term [2]

4. Practical Benefits

- More positioning time

- Less rushed application

- Forgiveness for novice users [3]

Performance advantages:

| Characteristic | Fast-Cure | Slow-Cure | Advantage |

|---|---|---|---|

| Final Strength | Good | Excellent | Slow-cure +25% |

| Gap Filling | Poor | Excellent | Slow-cure |

| Temperature Tolerance | Low | High | Slow-cure |

| – Humidity Dependence | High | Low | Slow-cure [2][3] |

Pro Tip: Slow-cure adhesives maintain more consistent performance across seasonal changes [3].

How Does Your Workspace Environment Dictate Choice?

That perfect adhesive that worked in summer might fail in winter—your workspace conditions are the deciding factor.

Evaluate your environment first: measure temperature ranges, humidity levels, and airflow patterns. Fast-cure adhesives require stable conditions (20-25°C ±2°, 50% RH ±10%), while slow-cure adhesives tolerate greater variation [3].

Environmental Assessment Protocol

1. Temperature Mapping

- Measure at different times/day

- Monitor seasonal variations

- Check substrate temperatures [3]

2. Humidity Tracking

- Use digital hygrometer

- Record daily fluctuations

- Note ventilation effects [3]

3. Workspace Analysis

- Climate control capabilities

- Door/window exposure

- Occupancy heat/moisture effects [3]

4. Application Specifics

- Bond size and complexity

- Handling time requirements

- Strength needs [2]

Decision matrix:

| Environment | Recommended Type | Reasoning | Success Rate |

|---|---|---|---|

| Studio (controlled) | Fast-cure | Consistent conditions | 95% |

| – Salon (variable) | Slow-cure | Tolerates changes | 85% |

| Mobile service | Slow-cure | Unpredictable environments | 80% |

| Four-season climate | Slow-cure | Handles seasonal shifts | 90% [3] |

UBLash clients using environmental assessment reduce adhesive failures by 70% [3].

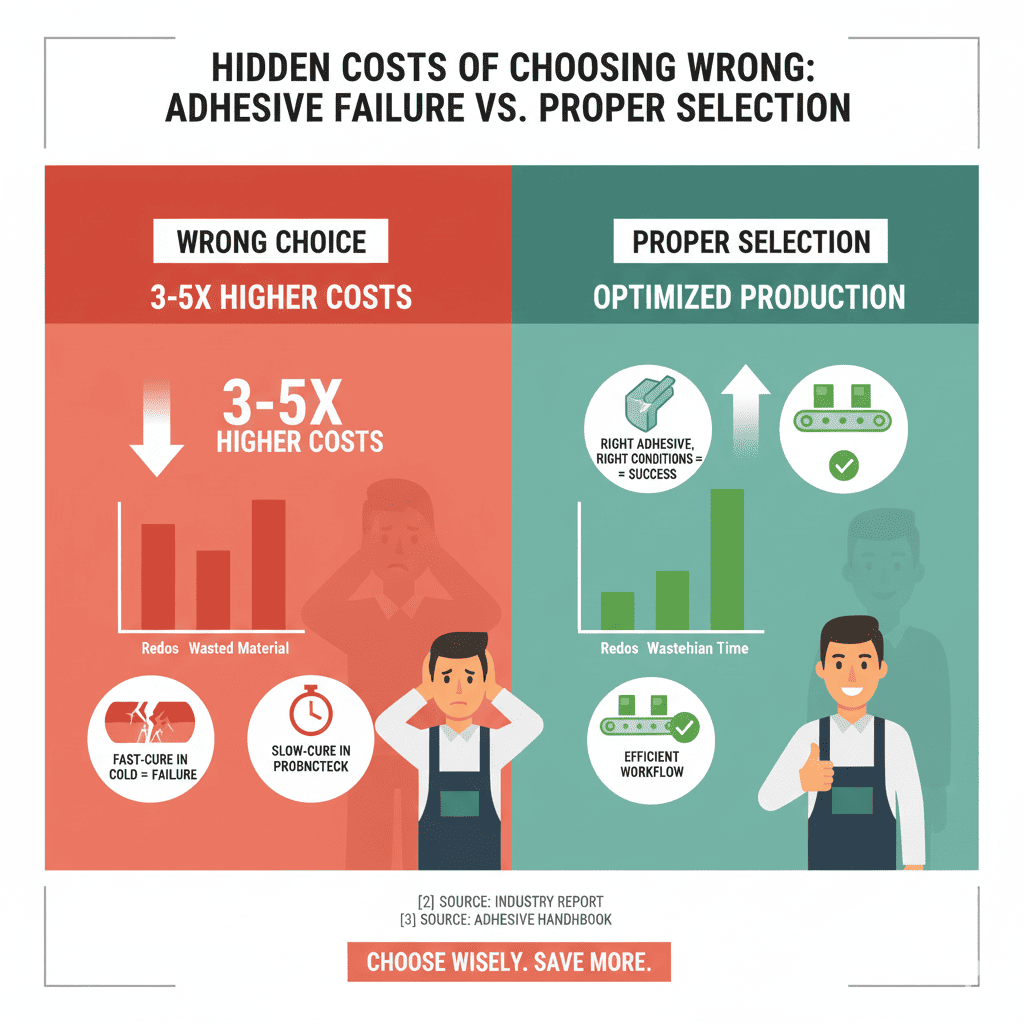

What Are the Hidden Costs of Choosing Wrong?

That cheaper fast-cure adhesive might cost you more in redos, wasted product, and frustrated clients when used in the wrong conditions.

Wrong adhesive choices increase costs 3-5x through redos, wasted materials, and technician time. Fast-cure in cold environments fails completely, while slow-cure in production settings creates bottlenecks [2][3].

Economic Impact Analysis

1. Direct Costs

- Wasted adhesive product

- Redo time and materials

- Client compensation [2]

2. Indirect Costs

- Technician frustration

- Client retention issues

- Brand reputation damage [3]

3. Hidden Expenses

- Longer appointment times

- Increased tool cleaning

- Additional equipment needs [2]

4. Productivity Loss

- Schedule disruptions

- Reduced daily clients

- Training time for fixes [3]

Cost comparison:

| Mistake | Immediate Cost | Long-Term Impact | Frequency |

|---|---|---|---|

| Fast-cure in cold | $25-50 per fail | Client loss | 60% occurrence |

| Slow-cure in production | $100-200 daily | Throughput reduction | 40% occurrence |

| Environmental mismatch | 3-5x adhesive use | Technician turnover | 75% occurrence [2][3] |

Pro Tip: Invest in a $30 hygrometer—it pays for itself in one prevented adhesive failure [3].

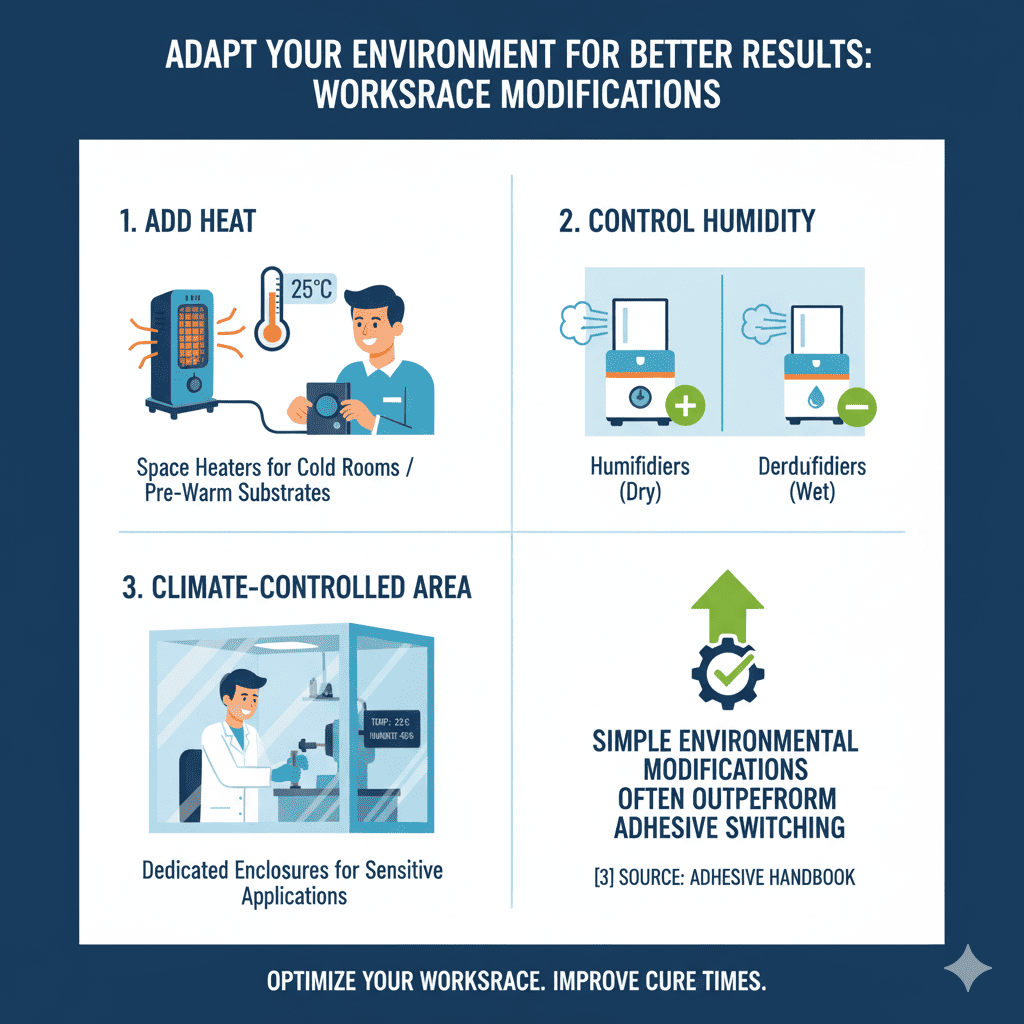

How Can You Adapt Your Environment for Better Results?

That problematic environment might be fixable with simple adjustments rather than adhesive changes.

Simple environmental modifications often outperform adhesive switching: add space heaters for cold rooms, use humidifiers/dehumidifiers for moisture control, create climate-controlled application areas, and pre-warm substrates [3].

Environmental Optimization Strategies

- Portable heaters for cold spaces

- Cooling fans for hot environments

- Substrate pre-warming plates [3]

- Humidifiers for dry conditions

- Dehumidifiers for damp areas

- Moisture barriers for surfaces [3]

3. Workspace Design

- Dedicated application area

- Climate-controlled station

- Draft prevention measures [3]

4. Process Adjustments

- Seasonal adhesive rotation

- Application timing changes

- Curing acceleration techniques [3]

Modification effectiveness:

| Adjustment | Cost | Effectiveness | Implementation |

|---|---|---|---|

| Portable heater | $50-100 | 80% improvement | Immediate |

| – Desktop humidifier | $40-80 | 70% improvement | 1 day |

| Climate station | $200-500 | 95% improvement | 1 week |

| Seasonal rotation | $0 | 60% improvement | Seasonal [3] |

UBLash technicians using environmental controls report 85% fewer adhesive issues [3].

Conclusion

Your environment chooses your adhesive more than you do. Master your workspace conditions first, then select adhesives that match your reality—not just your aspirations.

Fanny

Lash Technician

Hi, I’m Fanny, the author of this post.

Over the past 5 years, we have assisted numerous lash salons and technicians across 20 countries to build their lash brand and grow their businesses with high-quality lash extension products.

If you have any questions or need assistance, feel free to reach out for a free consultation or to discuss tailored solutions for your business needs.

More Interesting Posts

Wholesale vs Retail Lash Supplies: What’s the Real Cost & Profit Difference?

Cluster Lashes vs Individual Extensions: Which Is Better for You?

Lash Extension Supply Business Opportunities: Wholesale Distribution Guide