Launching a lash line is thrilling, but choosing the wrong manufacturer can lead to costly mistakes and damage your brand’s reputation before it even starts. Get the answers you need upfront.

Asking targeted questions about customization, quality control, MOQs, and support will help you select a private label lash manufacturer that aligns with your brand’s vision and ensures high-quality, safe products for your customers. 1

Embarking on your own lash line is a big step, and as someone who represents UBLash, a private label manufacturer, I know how vital clear communication is. These questions are your roadmap to finding a partner who can help you succeed, much like Sophie would meticulously vet her suppliers. Let’s dive in.

What Are the Typical Costs and Lead Times for Custom Packaging and Branding Services?

Worried about unexpected expenses and delays with your custom lash packaging? Unclear costs and timelines can derail your launch and eat into your profits.

Custom packaging and branding services can range from a few hundred to several thousand dollars, with lead times of 2-6 weeks, depending on complexity, materials, and the manufacturer’s capabilities.

When we work with new brands at UBLash, we aim for transparency here. The initial investment in branding and packaging is a key consideration. 2 It’s not just about a pretty box; it’s about creating an experience for your customer.

Breaking Down Packaging Costs & Timelines:

Several elements influence the cost and lead time for your bespoke lash packaging:

- Design Complexity: A simple logo print on a stock box will be quicker and cheaper than a fully custom-designed box with intricate graphics, special finishes (like foil stamping or embossing), and unique structural design.

- Materials: Standard cardboard is cost-effective. Premium materials like rigid board, textured papers, or eco-friendly options will increase costs and potentially lead times if they need to be specially sourced.

- Order Quantity: Larger orders usually mean a lower per-unit cost for packaging due to economies of scale in printing and production. However, the initial setup cost for custom printing plates or dies remains, which can make very small runs less economical.

- Printing Techniques: Full-color offset printing, spot UV, matte/gloss lamination – each adds a layer of cost and time.

- Manufacturer’s In-house vs. Outsourced Services: If the lash manufacturer handles packaging design and production in-house, it might be more streamlined. If they outsource it, lead times could extend.

| Element | Cost | Lead Time | Considerations |

|---|---|---|---|

| Simple Logo Print | Low | Short | Good for starting, quick turnaround. |

| Full Custom Design | Medium-High | Medium-Long | Creates strong brand identity, requires design work. 6 |

| Special Finishes | Medium-High | Medium | Adds premium feel (e.g., foil, emboss). |

| Custom Box Structure | High | Long | Unique unboxing experience, tooling costs. |

| Printing Volume | Per unit decreases with volume | Minimal after setup | Balances per-unit cost with upfront investment. |

| Packaging Element | Cost Impact | Lead Time Impact | Considerations |

|---|---|---|---|

| Simple Logo Print | Low | Short | Good for starting, quick turnaround. |

| Full Custom Design | Medium-High | Medium-Long | Creates strong brand identity, requires design work. 6 |

| Special Finishes | Medium-High | Medium | Adds premium feel (e.g., foil, emboss). |

| Custom Box Structure | High | Long | Unique unboxing experience, tooling costs. |

| Printing Volume | Per unit decreases with volume | Minimal after setup | Balances per-unit cost with upfront investment. |

Always request a detailed quote that breaks down these costs. Also, ask for a realistic timeline that includes design approval, proofing, production, and assembly. This helps manage expectations and your launch schedule effectively.

What Certifications and Quality Control Measures Does the Manufacturer Have to Ensure Product Safety?

Anxious about product safety and potential allergic reactions from your lash line? Substandard products can harm your customers and your brand’s credibility.

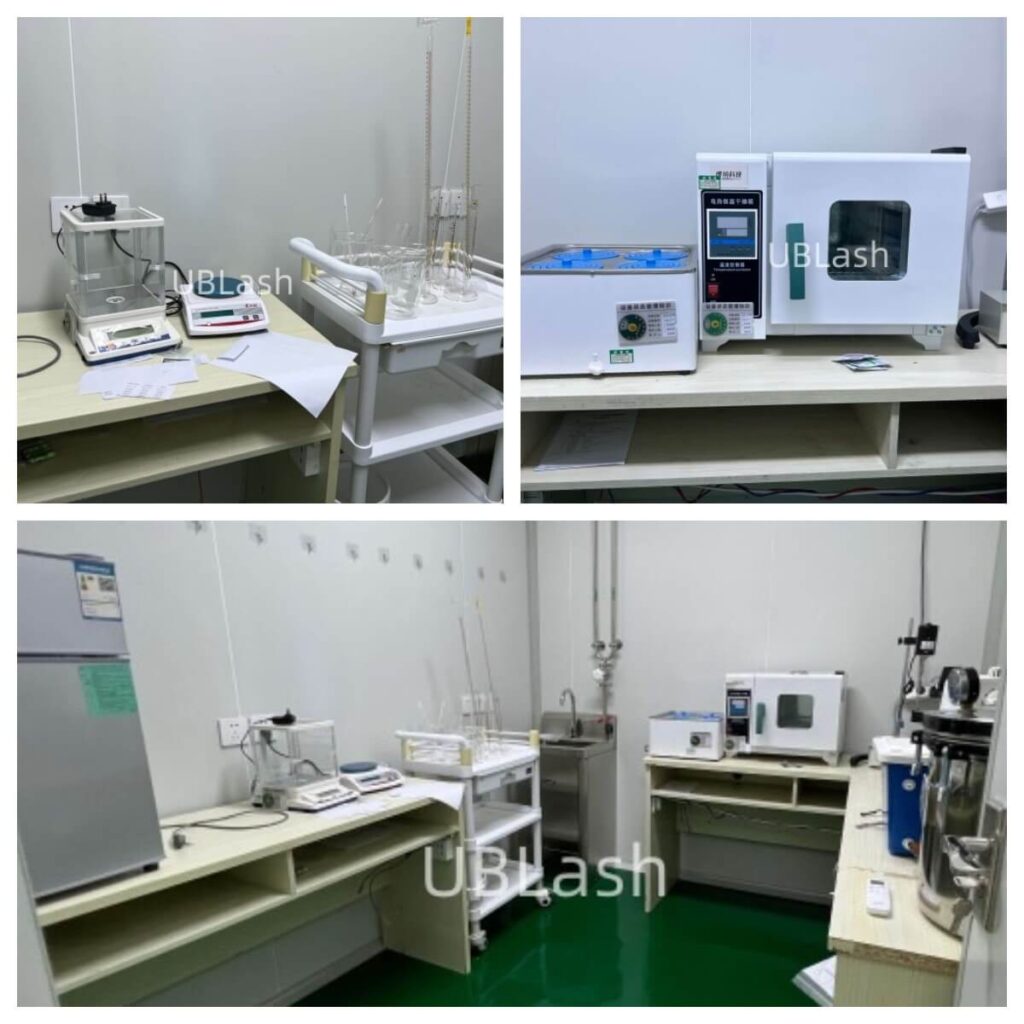

Reputable manufacturers should have ISO certifications (e.g., ISO 9001 for quality management), conduct rigorous material testing, and implement multi-stage quality control checks from raw materials to finished goods to ensure product safety. 1

At UBLash, product quality and safety are paramount. 1 We understand that for lash artists and brand owners like Sophie, knowing that the products are safe and reliable is non-negotiable. This isn’t just about looking good; it’s about client well-being.

Deep Dive into Safety and Quality Assurance:

Ensuring the safety of eyelash extensions and related products involves several layers of diligence from the manufacturer:

- Material Safety Data Sheets (MSDS): For all chemical components, especially in adhesives and removers, the manufacturer should be able to provide MSDS. These documents outline potential hazards and safe handling procedures.

- Fiber Quality: For lash extensions, this means using high-quality PBT or other approved synthetic fibers that are sterilized and free from harmful substances. Ask about the source and type of fibers.

- Adhesive Testing: Lash adhesives are a critical point. Inquire about testing for ingredients like formaldehyde (should be free), cyanoacrylate levels, and sensitization potential. Some markets have specific regulations (e.g., EU cosmetic regulations).

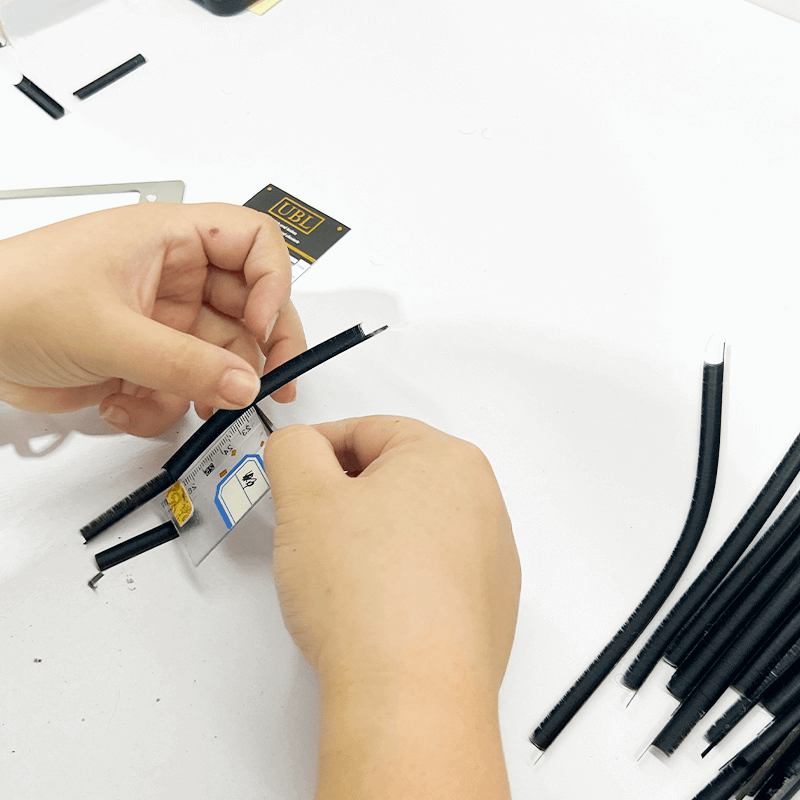

- In-Process Quality Checks: This includes checks at various stages: raw material inspection, during lash curling and setting, band attachment, and final product assembly.

- Finished Goods Inspection: Before packaging, products should be inspected for consistency in length, curl, thickness, and any defects.

- Batch Traceability: A good manufacturer will have a system to trace products by batch number. This is crucial if any issues arise post-market, allowing for targeted recalls if necessary.

| Quality Measure | Importance | What to Ask For |

|---|---|---|

| ISO Certifications | Demonstrates commitment to quality systems. | "Do you have ISO 9001 or other relevant certifications?" |

| Material Safety (MSDS) | Crucial for adhesives, removers. | "Can you provide MSDS for your adhesives/removers?" |

| Fiber Purity & Source | Ensures lashes are safe and consistent. | "What material are the lashes made from? Is it PBT? Is it sterilized?" |

| Adhesive Formulation | Critical for client safety & performance. | "Are your adhesives formaldehyde-free? What’s the cyanoacrylate type?" |

| QC Checkpoints | Ensures consistency and reduces defects. | "Can you describe your quality control process?" |

| Product Testing Reports | Independent verification of safety/quality. | "Do you have third-party testing reports for product safety?" 3 |

Don’t hesitate to ask for documentation. A transparent manufacturer will be forthcoming with this information. For someone like Sophie, who prioritizes quality, these details are essential for building trust.

Does the Manufacturer Offer Customization Options for Lash Styles, Lengths, Curls, and Packaging?

Want your lash line to truly reflect your unique brand vision but unsure if manufacturers can deliver? Generic products won’t help you stand out in a competitive market.

Most private label manufacturers offer extensive customization for lash styles (e.g., classic, volume, hybrid segments), lengths, curls, thicknesses, and comprehensive packaging design to match your brand identity. [1, 6]

[/caption]” alt=”alt text with descriptive keywords: A mood board showcasing diverse lash styles, curls, lengths, and custom packaging designs”>

This is where the creativity comes in! At UBLash, we love working with brands to develop their signature look. Customization is key to differentiating your products and building a loyal customer base. 6

Exploring the Spectrum of Customization:

The ability to customize is what truly makes a private label line yours. Here’s what you should explore:

- Lash Fiber Customization:

- Material: Confirm options like PBT, faux mink, silk finishes.

- Lengths: Specify ranges (e.g., 8mm to 16mm).

- Curls: Choose from J, B, C, CC, D, L, M, and more.

- Thicknesses: Options like 0.03mm, 0.05mm, 0.07mm, 0.10mm, 0.15mm, etc.

- Color: Beyond black, some offer brown or even vibrant colors.

- Lash Style & Design:

- Classic, Volume, Hybrid, Mega Volume.

- Pre-made Fans: Number of lashes per fan (2D, 3D, 10D, etc.), fan spread.

- Specialty Lashes: Wispy lashes, YY lashes, W lashes, Camellia lashes.

- Band Type: Clear band, black band, thinness of the band.

- Packaging Customization: 6

- Box Type: Paperboard, magnetic closure, slide-out, window boxes.

- Printing: Your logo, brand colors, artwork, product information, instructions. 6

- Inserts: Custom trays to hold lash strips or pots, informational cards.

- Labeling: For individual lash trays or adhesive bottles.

| Customization Area | Examples | Impact on Brand |

|---|---|---|

| Lash Fibers | Specific curl (e.g., M curl), thickness (e.g., 0.05mm) | Caters to specific client looks, quality perception. |

| Lash Styles | Unique pre-made fan designs, wispy mapping | Signature products, trend responsiveness. |

| Packaging Box | Custom shape, material, full-color branded print 6 | Brand recognition, premium feel, unboxing experience. |

| Inner Trays | Organization of lengths, branded lash strips | Professional presentation, ease of use for artist. |

| Labeling | Consistent branding on all components | Cohesive brand image, professional look. |

Discuss your ideal product specifications in detail. A good manufacturer will guide you on what’s feasible and trending. We often find clients like Sophie have a strong vision, and our job is to help bring that to life technically.

What Is the Manufacturer’s Experience and Reputation in the Eyelash Extension Industry?

Partnering with an inexperienced or disreputable manufacturer can be a disaster. How do you ensure they can reliably deliver quality and understand your needs?

Look for manufacturers with a proven track record, positive client testimonials, and several years of experience specifically in eyelash extension production and private labeling. Their industry standing often reflects their reliability. [1, 4]

At UBLash, our years in the B2B lash sector and focus on OEM/ODM for brands worldwide have taught us the nuances of this market. A manufacturer’s experience directly impacts product quality, innovation, and their ability to guide you. 1

Gauging Manufacturer Experience and Reputation:

A manufacturer’s history and standing in the industry are crucial indicators of their suitability as your private label partner. Here’s how to assess this:

- Years in Business: How long have they been manufacturing eyelash extensions? Longer often means more refined processes and stability.

- Specialization: Do they specialize in lash products, or is it just one part of a larger, unrelated business? Specialization often leads to deeper expertise.

- Client Portfolio/Testimonials: Can they share examples of other brands they’ve worked with (perhaps non-disclosure agreements limit specifics, but general experience is key)? Are there public reviews or testimonials? 4

- Trade Show Presence: Participation in major beauty and lash industry trade shows can indicate commitment and legitimacy.

- Understanding of Market Trends: An experienced manufacturer stays updated on new lash styles, materials, and application techniques. They can be a valuable source of advice.

- Export Experience: If you’re importing, like Sophie in Canada sourcing from China, their experience with international shipping, customs, and regulations for your specific region (e.g., North America, Europe) is vital.

| Aspect to Check | Why It Matters | Questions to Ask |

|---|---|---|

| Years of Operation | Indicates stability, process refinement. | "How long have you been manufacturing lash extensions?" |

| Lash Specialization | Deeper product knowledge, better quality control. | "Are lash products your primary focus?" |

| Client References | Proof of past performance, reliability. 4 | "Can you provide references or show examples of private label work?" |

| Industry Involvement | Legitimacy, awareness of standards & trends. | "Do you participate in industry trade shows?" |

| Export Markets | Familiarity with your region’s requirements. | "What are your main export countries? Are you familiar with Canadian/US/EU regulations?" |

Building a brand takes trust, and that starts with trusting your manufacturer. Don’t be shy about asking for proof of their experience and reputation. 1

What Are the Minimum Order Quantities (MOQs) and Pricing Structures for Private Label Lash Products?

Uncertain about how many units you need to order or how pricing works? MOQs and pricing can significantly impact your startup costs and profitability. 2

MOQs for private label lashes can vary widely (e.g., 50-200 units per style for lashes, higher for custom packaging). Pricing is often tiered, with discounts for larger volumes. [1, 2]

%[alt text with descriptive keywords: Stacks of lash boxes with different quantity numbers and price tags showing volume discounts](Private Label lash](http://ublash.com/wp-content/uploads/2025/01/Hcdc43362cd2942bca90e9832c02aedc3z-1.webp)

We understand that for new brands, MOQs can be a concern. At UBLash, we aim for accessible MOQs for private label clients because we want to support emerging businesses. Clear pricing is also fundamental. 1

Navigating MOQs and Pricing:

Understanding a manufacturer’s MOQs and pricing is essential for financial planning and inventory management.

- Product-Specific MOQs: MOQs can differ for various items. For example, the MOQ for lash trays might be 100 units per style/length/curl, while the MOQ for a custom-printed box could be 500 or 1000 units due to printing press minimums. Adhesives might have their own MOQs.

- Tiered Pricing: Most manufacturers offer better per-unit prices for larger order quantities. Ask for their price breaks (e.g., price for 100 units vs. 500 units vs. 1000 units).

- Setup Costs: For custom packaging or new lash designs, there might be one-time setup fees for molds, printing plates, or design work. Clarify if these are separate or included in the unit price.

- Sample Costs: While some manufacturers offer free samples (you might pay for shipping), others charge for them, especially for customized samples. This cost is sometimes credited back if you place a bulk order.

- Payment Terms: Understand the required deposit (usually 30-50%), balance payment terms (often before shipping), and accepted payment methods.

| Factor | Typical Structure | What to Clarify |

|---|---|---|

| Lash Trays | MOQ per SKU (e.g., 50-200 units of C curl 0.07 12mm) | "What is the MOQ per specific lash type, curl, length, and thickness?" |

| Packaging | Higher MOQ (e.g., 500-1000 boxes) due to printing | "What’s the MOQ for custom boxes? Are there different MOQs for different box styles?" |

| Adhesives | Often per bottle or small batch size | "What is the MOQ for private label adhesives?" |

| Pricing | Tiered based on volume 1 | "Can you provide a price list with volume discounts?" |

| Setup Fees | Possible for custom molds/printing plates 2 | "Are there any one-time setup fees for custom designs or packaging?" |

| Payment Terms | Deposit + Balance before shipping | "What are your payment terms and accepted methods?" |

Don’t just look at the per-unit price. Consider the total cost of ownership, including MOQs for all components, setup fees, and shipping. This overall picture is crucial for someone like Sophie managing her business’s profitability.

How Flexible Is the Manufacturer Regarding Design Changes and Packaging Customization?

Have a specific vision for your lash brand but worried a manufacturer might be too rigid? Lack of flexibility can stifle your creativity and brand uniqueness.

A good private label manufacturer should offer reasonable flexibility for design changes and packaging customization, especially during the development phase. Clear communication about capabilities and limitations is key. 6

[/caption]” alt=”alt text with descriptive keywords: Designer collaborating with a client over packaging mockups, showing iterations”>

At UBLash, we see private labeling as a collaborative process. 6 While there are technical limits, our goal is to accommodate our clients’ visions as much as possible, because a unique brand identity is vital.

Assessing Design and Packaging Flexibility:

A manufacturer’s willingness to adapt and customize is a significant factor in a successful private label partnership.

- Iterative Design Process: Ask if they support an iterative design process, allowing for mock-ups, revisions, and feedback before finalizing designs for lash styles or packaging.

- Range of Packaging Options: Do they offer a wide variety of existing packaging templates you can brand, or are they adept at creating entirely new packaging structures based on your ideas? 6

- Material Sourcing: If you want specific, perhaps unconventional, packaging materials, how willing and able are they to source these for you?

- Minimum Changes for Customization: Some manufacturers might have minimum complexity or order size requirements before they consider significant deviations from their standard offerings.

- Changes Post-Approval: Understand the policy and potential costs if you need to make changes after a design has been approved and production (or tooling) has begun. This is usually costly and best avoided.

- Graphic Design Support: Do they have in-house designers who can help you refine your artwork, or do you need to provide print-ready files?

| Aspect of Flexibility | What to Look For | Potential Limitations |

|---|---|---|

| Initial Design Iterations | Willingness to provide multiple mock-ups/revisions. | May charge for excessive revisions beyond an agreed scope. |

| Custom Packaging Structure | Ability to create unique box shapes/inserts. 6 | Higher tooling costs, longer development time for complex shapes. |

| Material Choices | Access to diverse and specialty materials. | Some materials may have high MOQs or sourcing difficulties. |

| Print Finish Options | Offers various finishes (foil, emboss, spot UV). | Each special finish adds cost and may have minimum runs. |

| Minor Adjustments | Accommodating small tweaks to standard lash styles. | Drastic changes might classify as full OEM, with different terms. |

A manufacturer that values your brand’s uniqueness will be more of a partner than just a supplier. Sophie, with her assertive nature, would appreciate a manufacturer who is open to discussion and collaboration on design.

What Is the Typical Lead Time for Production and Delivery of Private Label Lash Orders?

Need your lash products by a certain date but unsure how long it all takes? Miscalculating lead times can mean missed launch dates or stockouts.

Typical lead times for private label lash orders, including production and international delivery, range from 3 to 4 weeks, varying by order complexity, quantity, customization, and shipping method. [2, 5]

Managing expectations around lead times is crucial. [2, 5] At UBLash, we provide estimated timelines upfront, factoring in all stages from order confirmation to final delivery, so our clients can plan accordingly.

Understanding the Components of Lead Time:

Lead time isn’t just manufacturing; it’s a multi-stage process:

- Pre-Production (1-2 weeks): This includes finalizing designs, sample approval (if any final tweaks), deposit payment, and raw material confirmation/ordering by the factory.

- Production (2-6 weeks): This is the actual manufacturing of the lashes and custom packaging. It depends heavily on:

- Order Volume: Larger orders take longer.

- Complexity: Intricate lash designs or complex packaging require more time.

- Factory’s Current Schedule: A busy factory will have a longer queue.

- Quality Control & Packing (3-7 days): Thorough inspection and careful packing before shipment.

- Shipping (1-5 weeks): This varies dramatically:

- Express Courier (e.g., DHL, FedEx): 3-7 days (most expensive).

- Air Freight: 5-14 days (moderate cost).

- Sea Freight: 3-5 weeks (most cost-effective for bulk, but slowest). For clients like Sophie in Canada sourcing from China, sea freight is common for larger orders.

- Customs Clearance (Variable): Can take a few days to over a week, depending on the port and paperwork.

| Stage | Estimated Duration | Key Factors Affecting Duration |

|---|---|---|

| Order Confirmation & Deposit | 1-3 Days | Your promptness, factory’s processing time. |

| Pre-Production/Sampling | 1-2 Weeks | Design finalization, material sourcing. |

| Mass Production | 2-6 Weeks | Order size, complexity, factory workload. [2, 5] |

| Quality Control | 2-5 Days | Thoroughness of inspection. |

| Packaging & Dispatch | 2-5 Days | Boxing, labeling, arranging shipment. |

| International Shipping | 1-5 Weeks | Chosen method (air/sea/courier), destination, customs. |

Always confirm lead times before placing your order and factor in potential buffer time for unexpected delays, especially around peak seasons or holidays like Chinese New Year.

Can the Manufacturer Provide Samples for Quality Evaluation Before Placing a Bulk Order?

Hesitant to commit to a large order without first seeing and testing the products? Investing in inventory without quality assurance is a huge risk.

Yes, reputable private label lash manufacturers should always provide samples for quality evaluation before you commit to a bulk order. This is a critical step to ensure products meet your standards. 3

At UBLash, we insist on clients evaluating samples. 3 It’s essential for building trust and ensuring that what you envision for your brand is what we deliver. Sophie would definitely prioritize this.

The Importance and Process of Sampling:

Samples are your first tangible interaction with your potential product line. Don’t underestimate their value.

- Purpose of Samples:

- Quality Assessment: Check lash fiber softness, curl consistency, band quality, and overall craftsmanship. 3

- Adhesive Testing (if applicable): Evaluate drying time, bond strength, and potential fumes (though full allergy testing is complex).

- Packaging Review: Examine print quality, material feel, and structural integrity of sample packaging.

- Wear Test: Apply the lashes (or have testers do so) to check for comfort, durability, and appearance.

- Types of Samples:

- Stock Samples: Existing products from the manufacturer’s line. Good for initial quality assessment of their general capabilities.

- Customized Samples: Samples made to your specific lash design or with your branding on stock packaging. These may have a cost, sometimes credited upon bulk order.

- What to Ask Regarding Samples:

- "Can I order samples of the specific lash styles I’m interested in?"

- "Is there a cost for samples? Is it refundable with a bulk order?"

- "How long will it take to receive samples?"

- "Can you provide samples of different packaging options or material swatches?"

| Sample Aspect | Why It’s Crucial | What to Evaluate |

|---|---|---|

| Lash Fiber Quality | Directly impacts client comfort & look. 3 | Softness, consistency of curl/length, no kinks. |

| Lash Band | Affects application ease & comfort. | Flexibility, thinness, durability, even lash distribution. |

| Adhesive (if incl.) | Performance and safety. | Fumes, dry time, initial bond (patch test recommended). |

| Packaging | First impression of your brand. | Print quality, material, construction, design accuracy. 6 |

| Overall Craftsmanship | Reflects manufacturer’s attention to detail. | Uniformity, no loose fibers, neatness. |

Thoroughly testing samples is a non-negotiable step before investing in a large inventory. 3 It protects your investment and your brand’s future reputation.

How Does the Manufacturer Handle Regulatory Compliance and Testing for Lash Safety?

Concerned about navigating the complex world of product safety regulations? Selling non-compliant products can lead to legal issues and harm your customers.

A responsible manufacturer should be aware of and comply with relevant cosmetic regulations in your target markets (e.g., EU, FDA in the USA), conduct necessary safety tests (like for adhesives), and provide documentation. [1, 3]

At UBLash, we understand the importance of compliance, especially when exporting to regions like Europe and North America with stringent standards. 1 Ensuring product safety through proper testing and adherence to regulations is a priority. 3

Navigating Lash Safety Regulations:

Lash products, particularly adhesives, are subject to cosmetic and chemical regulations that vary by country/region.

- Key Regulatory Bodies:

- EU: Governed by the EU Cosmetic Regulation (EC) No 1223/2009. Requires a Product Information File (PIF), safety assessments, and notification.

- USA: FDA (Food and Drug Administration) regulates cosmetics but doesn’t pre-approve them (except color additives). However, products must be safe and properly labeled.

- Canada: Health Canada regulates cosmetics under the Food and Drugs Act and Cosmetic Regulations. Notification is required.

- What to Ask Your Manufacturer:

- "Are you familiar with the cosmetic regulations in [your target country/region]?"

- "Can you provide safety data sheets (MSDS/SDS) for your adhesives and removers?"

- "Do your products undergo specific testing for irritants or harmful substances (e.g., formaldehyde, heavy metals)?"

- "Can you assist with providing documentation needed for regulatory compliance in my market?"

- Manufacturer’s Role vs. Your Responsibility: While the manufacturer should ensure their products are made safely, the brand owner (you) is ultimately responsible for ensuring the products comply with all local regulations in the market where they are sold. This includes proper labeling with ingredient lists, warnings, and manufacturer/distributor details.

| Regulatory Aspect | Manufacturer’s Responsibility | Your Responsibility |

|---|---|---|

| Safe Formulation | Use safe, approved ingredients; avoid banned substances. [1, 3] | Verify ingredients against local regulations. |

| Good Manufacturing Practices (GMP) | Produce in a clean, controlled environment. | Inquire about their GMP standards (ISO 22716 is ideal). |

| Safety Testing (e.g., for adhesives) | Conduct or provide access to relevant test reports. 3 | Request and review safety documentation. |

| Basic Labeling Info | Provide accurate ingredient lists, batch codes. | Ensure final product labels meet all local requirements. |

| Export Documentation | Provide necessary paperwork for customs. | Ensure all import/export regulations are met. |

It’s wise to consult with a regulatory expert familiar with your specific market to ensure full compliance, especially for products like adhesives. A proactive manufacturer will be a helpful partner in this.

What Support and Communication Can I Expect from the Manufacturer During and After the Order Process?

Worried about being left in the dark after placing an order or facing issues alone? Good communication and support are vital for a smooth partnership. 1

Expect prompt, clear communication, a dedicated contact person, updates during production, and assistance with any post-delivery issues. The level of support often reflects the manufacturer’s professionalism. 1

At UBLash, we believe ongoing communication and support are key to a successful B2B relationship. 1 From initial inquiry to after-sales service, we aim to be responsive and helpful, knowing that our client’s success is our success.

Evaluating Manufacturer Support and Communication:

Effective support extends beyond just taking your order.

- Pre-Order Support:

- Responsiveness: How quickly and thoroughly do they answer your initial questions?

- Clarity: Is their information clear and easy to understand?

- Guidance: Do they offer helpful advice on product selection or customization? 1

- During Production Support:

- Dedicated Contact: Will you have a single point of contact for your order?

- Proactive Updates: Will they provide updates on production milestones without you constantly chasing them?

- Problem Resolution: How do they handle potential production delays or issues?

- Post-Delivery Support:

- Addressing Discrepancies: What is their process if there are quality issues or shortages with the delivered order?

- Warranty/Guarantee: Do they offer any warranty on their products?

- Feedback Mechanism: Are they open to feedback for future orders?

- Communication Channels: What methods do they use (email, phone, messaging apps like WhatsApp/WeChat)? Is there a language barrier, and how is it managed?

| Support Phase | Key Expectations | Red Flags |

|---|---|---|

| Pre-Order | Prompt replies, clear quotes, helpful advice. 1 | Slow responses, vague answers, pressure tactics. |

| During Production | Dedicated contact, regular updates, transparency. | Difficult to reach, no updates, dismissive of concerns. |

| Post-Delivery | Help with issues (quality, damages), clear return/fix policy. | No accountability for problems, blames shipping, ignores emails. |

| Overall Comm. | Professional, respectful, timely, clear language. 1 | Frequent misunderstandings, unprofessional tone, language barriers. |

For Sophie, who is assertive and values efficiency, clear and reliable communication would be a top priority. Inefficient communication is one of her listed pain points with suppliers, so this is a critical area to vet.

How Diverse Is the Manufacturer’s Product Range to Cater to Different Customer Preferences and Market Trends?

Want to offer a variety of lash products but concerned a manufacturer might have limited options? A narrow range can restrict your brand’s growth and appeal.

A good manufacturer should offer a diverse product range, including various lash types (classic, volume, pre-mades, specialty), curls, lengths, thicknesses, adhesives, and accessories, to cater to evolving market trends.

At UBLash, we pride ourselves on offering a comprehensive selection of lash extension products. This allows the brands we partner with to curate a versatile line that meets diverse customer preferences and stays current with industry innovations.

Assessing Product Range and Innovation:

A manufacturer with a broad and up-to-date product portfolio can be a valuable asset.

- Core Lash Extensions:

- Types: Classic, Volume (Russian Volume), Hybrid, Pre-made Fans (various Ds), YY/W/Clover lashes, Camellia lashes.

- Materials: High-quality PBT in different finishes (matte/semi-matte/slight sheen).

- Curls, Lengths, Thicknesses: A wide array of options in each category.

- Adhesives & Liquids:

- Different types of adhesives (for varying humidity, dry times, sensitivities).

- Primers, bonders, sealants, removers (gel, cream).

- Tools & Accessories:

- Tweezers (isolation, application, volume).

- Under-eye pads, tapes, lash brushes, micro-swabs, glue rings/palettes.

- Innovation & Trend Awareness:

- Do they introduce new products regularly?

- Are they aware of and able to produce newer trending styles (e.g., "Manga" lashes, "Wet look" lashes)?

- Ability to Source/Develop: If they don’t currently stock an item you need, are they willing and able to source or develop it for your private label line?

| Product Category | Importance for Your Brand | What to Look For in Manufacturer’s Range |

|---|---|---|

| Lash Extensions | Core offering, needs variety for different client looks. | Diverse curls, lengths, thicknesses, styles (pre-mades). |

| Adhesives | Crucial for performance and client safety. | Options for different skill levels, sensitivities, environments. |

| Application Tools | Essential for lash artists using your line. | Quality tweezers, pads, tapes, brushes. |

| Aftercare Products | Opportunity for add-on sales, client retention. | Cleansers, sealants, growth serums (if applicable). |

| New Trends | Keeps your brand fresh and competitive. | Evidence of new product development, awareness of trends. |

A manufacturer that actively expands its offerings and stays on top of trends can help your brand evolve and capture new market segments. Sophie, always willing to try new industry products, would value a supplier who is innovative.

Conclusion

Asking these key questions will empower you to choose the best private label lash manufacturer, ensuring quality, safety, and a strong foundation for your brand’s success. [1, 3]

Fanny

Lash Technician

Hi, I’m Fanny, the author of this post.

Over the past 5 years, we have assisted numerous lash salons and technicians across 20 countries to build their lash brand and grow their businesses with high-quality lash extension products.

If you have any questions or need assistance, feel free to reach out for a free consultation or to discuss tailored solutions for your business needs.

More Interesting Posts

Wholesale vs Retail Lash Supplies: What’s the Real Cost & Profit Difference?

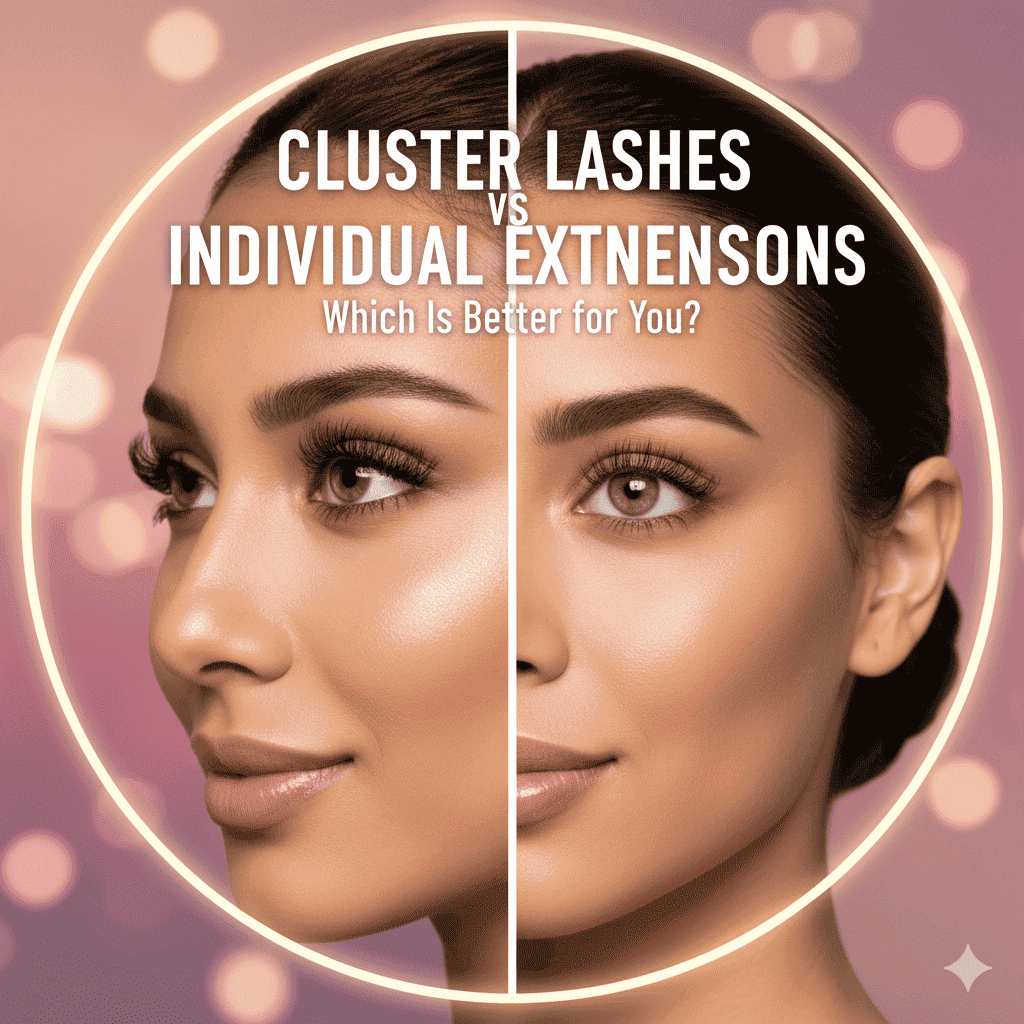

Cluster Lashes vs Individual Extensions: Which Is Better for You?

Lash Extension Supply Business Opportunities: Wholesale Distribution Guide