Are you tired of inconsistent lash trays that damage your reputation? One bad batch can lead to unhappy clients and wasted money. Let’s explore what truly separates premium lash trays from the rest.

A high-quality lash tray is defined by its core components. This includes the use of superior PBT material for softness and curl stability, perfect curl consistency across every lash, a deep and rich color, and an easy-to-use adhesive strip. These features ensure a flawless application and stunning results.

As a lash supplier, I’ve seen it all. I’ve talked to countless salon owners like you who are frustrated with the gamble of ordering new inventory. You need reliability, not just a low price. So, let’s break down the essential elements that guarantee you’re getting the best. We will look at everything from the raw material to the small details on the strip.

Why is high-grade PBT material the gold standard for lash extensions?

Have your clients ever mentioned that their extensions feel stiff or plastic-like? Using low-grade materials can cause discomfort, irritation, and even poor retention, which hurts your business in the long run.

The secret to soft, durable, and natural-feeling lashes lies in Polybutylene Terephthalate, or PBT. This high-performance polymer is sterilized and processed to create extensions that are lightweight yet strong. It holds a curl perfectly without ever losing its shape, even when exposed to heat or water.

Diving Deeper into PBT Grades

Not all PBT is created equal. The quality of the raw material directly impacts the final product. As a private label owner, understanding this is key to building a brand known for excellence. Think of it like cooking; a great chef needs the best ingredients. For me, sourcing the highest grade of PBT from trusted suppliers in Korea and Germany is non-negotiable. This decision affects everything from the lash’s texture to its ability to hold a curl. Lower-grade PBT often contains impurities, resulting in lashes that are heavier, less flexible, and have an unnatural glossy shine. This can cause discomfort for the client and make the application process harder for the technician. High-grade PBT, on the other hand, is refined to be incredibly soft and lightweight, closely mimicking the feel of natural lashes.

Here is a simple breakdown of the differences:

| Feature | High-Grade PBT | Low-Grade PBT |

|---|---|---|

| Source | Reputable suppliers (e.g., Korea, Germany) | Undisclosed or cheaper sources |

| Texture | Extremely soft and flexible | Stiff, coarse, or plastic-like |

| Weight | Very lightweight for client comfort | Heavier, may strain natural lashes |

| Finish | Natural matte or semi-matte | Unnaturally glossy or shiny |

| Purity | High purity, fewer impurities | Contains more impurities |

| Curl Retention | Excellent, stable over time | Prone to relaxing or straightening |

When I work with clients to develop their own lash line, the first conversation we have is about PBT. It’s the foundation of a premium product.

How do top suppliers guarantee curl consistency in every single lash?

You open a new C-curl tray, but it looks more like a D-curl. Or worse, the curls are inconsistent on the same strip. This frustrating experience wastes time and compromises the quality of your sets.

Top-tier manufacturers achieve perfect curl consistency through a meticulous, heat-setting process. Lashes are carefully shaped on custom-designed cylinders and then heated and cooled multiple times. This method locks the curl in place, ensuring every single lash maintains its intended shape from the factory to your client’s eye.

Diving Deeper into the Curl Manufacturing Process

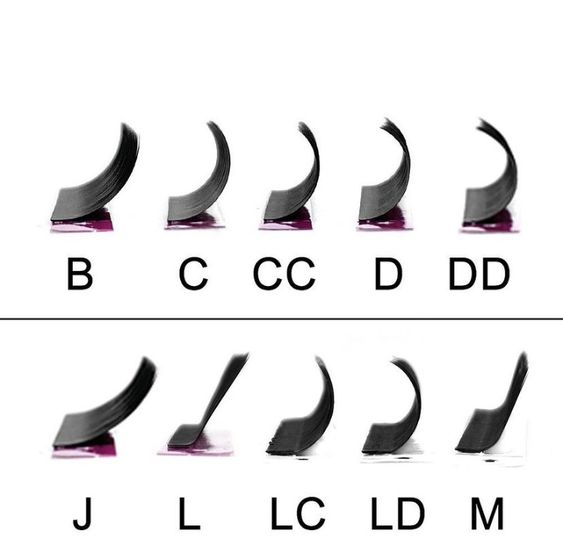

The process of creating a perfect, stable curl is more science than art. It’s something I personally inspect when vetting new production partners. It involves precise control over temperature, timing, and tension. Any deviation can lead to the inconsistencies that drive lash artists crazy. The lashes are hand-rolled onto small, cylindrical rods, with the diameter of the rod determining the specific curl (J, B, C, CC, D, L, etc.). These rods are then placed in a specialized oven where they undergo a double heat-treatment. This process ensures the PBT material’s "memory" is set to the desired curl. It’s a delicate balance; too much heat can make the lashes brittle, while not enough will cause the curl to relax over time, especially after getting wet.

Here’s a look at the factors that ensure curl stability:

Key Factors in Curl Production

| Factor | High-Quality Process | Low-Quality Process |

|---|---|---|

| Temperature Control1 | Precisely calibrated ovens | Inconsistent or uncalibrated heating |

| Heating Method | Double or triple heat treatment | Single, rushed heat treatment |

| Cylinders/Rods | Custom-made, uniform diameter | Worn-out or inconsistent rods |

| Cooling Process | Controlled cooling to set the shape | Rapid or uncontrolled cooling |

| Quality Control2 | Each batch is tested for consistency | Spot checks or no checks at all |

I remember a time when a new client, "Sophie," told me about her previous supplier. Her D-curl trays would sometimes look like C-curls after a week of wear. This is a direct result of a rushed, single-heat process. That’s why at UBLash, we insist on a double-heat treatment. It’s a small step that makes a huge difference in brand reputation.

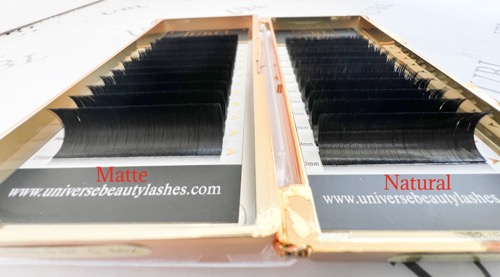

Does the color and finish of a lash extension really impact the final look?

Do some black lashes look faded or have a blueish tint? Have you ever noticed a client’s extensions looking obviously fake because they were too shiny? This small detail can undermine an otherwise perfect application.

Absolutely. The ideal lash extension has a deep, true black color without any discolored undertones. It should also have a natural matte or semi-matte finish. This prevents the cheap, plastic-like reflection that glossy lashes create, resulting in a more luxurious and seamless blend with the natural lashes.

Diving Deeper into Color and Finish

The color and finish are not just about aesthetics; they are indicators of material quality and manufacturing care. Achieving a true, deep matte black is a specialized process. It requires high-quality dyes that are integrated into the PBT material before it is extruded into fibers. Cheaper production methods often involve surface-level dyes that can fade over time or contain impurities, leading to a blue or gray hue, especially under bright light. The finish—matte versus gloss—is determined by the surface texture of the lash fiber itself. A matte finish is created by micro-scratches on the surface that diffuse light, whereas a glossy finish is perfectly smooth and reflects light directly. While some clients might prefer a dramatic, glossy look, a matte finish is overwhelmingly preferred by lash artists because it looks more natural and sophisticated. It absorbs light rather than reflecting it, creating an appearance of density and depth at the lash line.

Here’s how they compare and why it matters to your business:

Matte vs. Glossy Finish

| Feature | Matte Finish1 | Glossy Finish2 |

|---|---|---|

| Appearance | Deep, dark, and absorbs light | Shiny, reflects light, can look plastic-like |

| Client Perception | Luxurious, high-end, natural | Can look cheap or artificial |

| Blending | Blends seamlessly with natural lashes | Creates a noticeable contrast |

| Adhesive Bond | Slightly more porous surface can aid adhesion | Smooth surface can be trickier for adhesive to grip |

When you’re building a private label brand, choosing a matte finish tells your customers that you prioritize quality and a sophisticated result. It’s a subtle but powerful message.

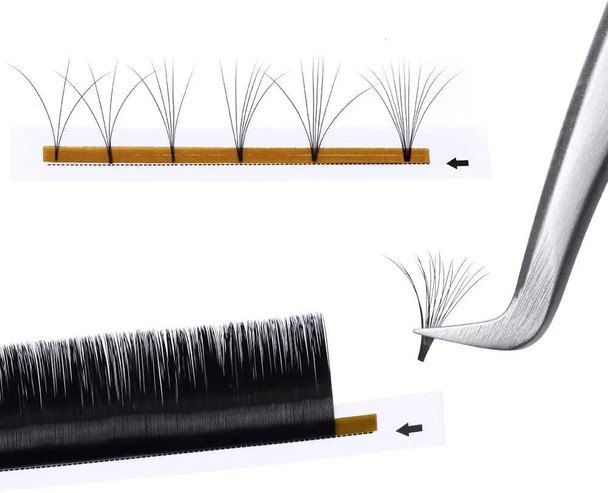

What makes an adhesive strip easy to work with for a lash artist?

Are you struggling to pick up lashes from the strip? Do they leave behind a sticky residue on your tweezers, or do your fans fall apart before you can even grab them? This directly impacts your speed and efficiency.

An ideal adhesive strip has just the right amount of tackiness. It should hold the lashes firmly in place for transport but release them effortlessly when picked with tweezers. The strip should not leave any sticky residue on the lash base, which is crucial for perfect fan-making and strong retention.

Diving Deeper into Adhesive Strip Technology

The "sweet spot" for adhesive strips is a major focus for us. As someone who talks to lash artists daily, I know that a bad strip can ruin a whole tray, no matter how good the lashes are. The technology behind these strips involves the type of adhesive used and how it’s applied. High-quality strips often use a specially formulated tape that provides a medium tack. The backing paper is equally important. Many top suppliers, including us at UBLash, use foil-backed strips. This is a game-changer. When a lash artist removes a strip from the tray to place it on their tile, a foil back ensures it peels off cleanly and can be re-stuck multiple times without losing its grip or leaving paper residue behind. Paper-backed strips, in contrast, often tear and leave a sticky, messy residue that is impossible to clean.

Let’s examine the details that create a perfect strip:

Characteristics of a Pro-Grade Adhesive Strip

| Characteristic | High-Quality (e.g., Foil Back) | Low-Quality (e.g., Paper Back) |

|---|---|---|

| Adhesive Tack | Medium tack, easy release | Too sticky or not sticky enough |

| Residue | Leaves no residue on lashes or tweezers | Leaves sticky residue, affecting bonding |

| Backing Material | Foil or high-grade plastic | Paper |

| Reusability | Can be moved multiple times | Tears or loses stickiness after one placement |

| Cleanliness | Stays clean on palettes/tiles | Leaves paper residue, hard to clean |

For lash trainers like Sophie, teaching students on trays with poor-quality strips is a nightmare. It creates bad habits and frustration. Providing your artists and students with equipment that works for them, not against them, is a simple way to elevate your brand and their work. This is why we’ve made foil-backed strips a standard for all UBLash products.

Conclusion

A "high-quality" lash tray isn’t just one thing. It’s the sum of many small, but vital, details working together to create a product that is reliable, beautiful, and easy to use.

Fanny

Lash Technician

Hi, I’m Fanny, the author of this post.

Over the past 5 years, we have assisted numerous lash salons and technicians across 20 countries to build their lash brand and grow their businesses with high-quality lash extension products.

If you have any questions or need assistance, feel free to reach out for a free consultation or to discuss tailored solutions for your business needs.

More Interesting Posts

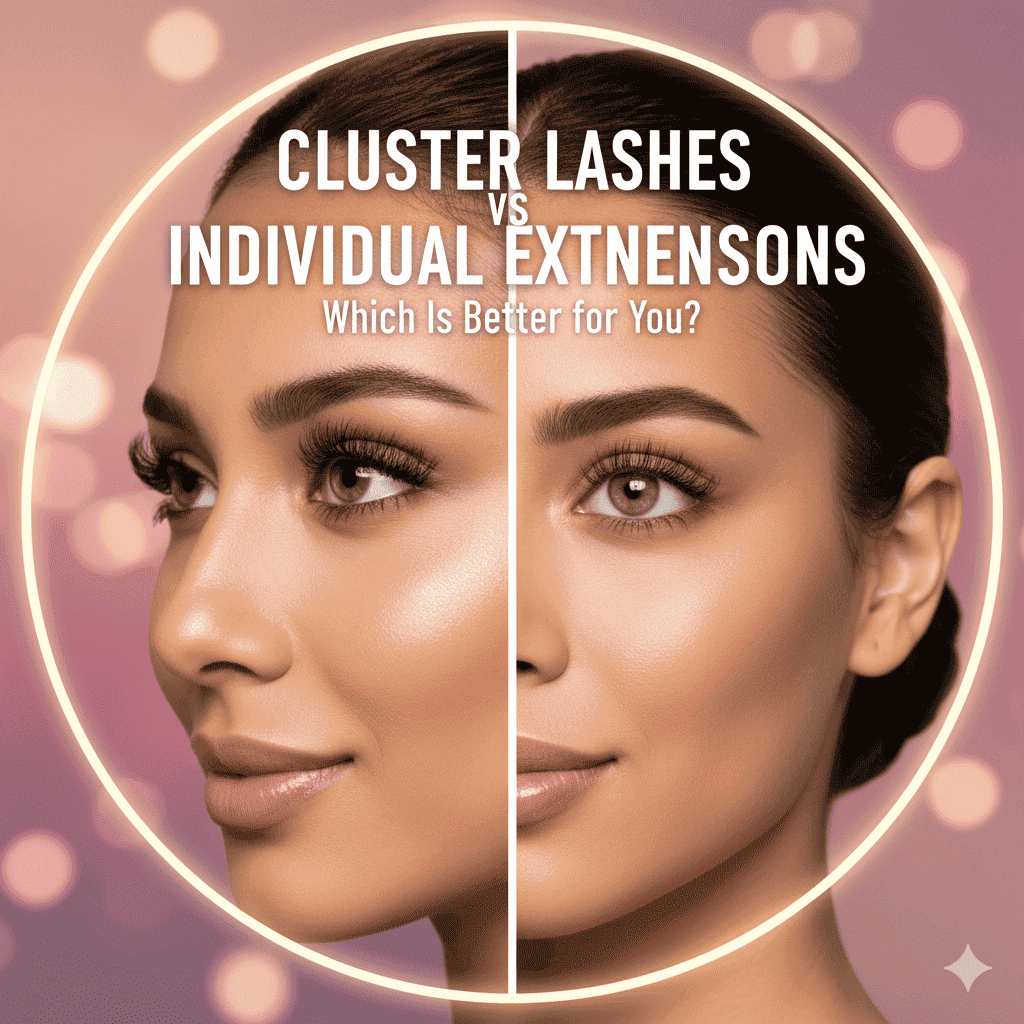

Cluster Lashes vs Individual Extensions: Which Is Better for You?

Lash Extension Supply Business Opportunities: Wholesale Distribution Guide

When to Use L Curl Lashes: The Perfect Choice for Hooded and Droopy Eyes?